| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

APACK AMBALAJ MAKİNE SAN. VE TİC. LTD. ŞTİ.

Ferhatpaşa Mahallesi 22. Sokak No: 43 34888 / Ataşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 541 234 6270

|

Hall: 11

Stand: 1109B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

APACK was founded in 2004 and began producing its own food and medical packaging machines in 2014, offering cutting-edge packaging solutions to customers worldwide. Our machines meet international standards and are currently exported to over 60 countries. Starting with MAP25, we have expanded our product line to include 25 different models across 8 subcategories, all produced in our state-of-the-art facilities in Istanbul. Regardless of the model, we approach every machine with the same level of care, quality, and use of modern technologies. Our product range spans from practical desktop models to fully automated packaging machines. User-Friendly Solutions APACK machines are highly customizable to meet each customer s specific demands and needs. They are designed to be user-friendly, easy to clean, and easy to maintain. All machines are made of AISI304 stainless steel, following world standards. The automatic machines are controlled via touch screens and can also be remotely controlled through an internet connection. The APACK machines are also compatible with various Packaging Line Accessories, such as Tray Denester, Multihead Portioner, Weigher, liquid or solid Automatic Filler, Printer, Labeller, Conveyor, Metal Detector, UV Scanner, and Gas Mixers. Customers can also benefit from our Spare Parts, Technical Service, and machine use and maintenance training.

DOTS/SC-TABLETOP20 SERIES are the most practical solution for your small-scale productions. It is economical, fits up little space, consumes less electricity, is easy to use and transport, and is trouble-free to clean. It is a fixed mold system with 1-4 pieces depending on the design of the packaging. Only suitable for packaging that requires sealing. It gives efficient results especially on paper/cardboard trays used for takeaways. It is a budget friendly solution in low volume productions. It provides packaging support suitable for daily consumptions that do not require shelf life such as sandwiches, breakfasts, takeaways. In the using of flexible film, sealing and cutting processes are done together. Thanks to its feature of cleaning the excess on the edge and leaving no residue during sealding, it allows you to present a clean and neat looking product to your customer. Packaging materials suitable for both hot and cold service can be used. It is suitable for the use of printed and multi-layer films. It is produced with stainless steel and cast material. You can provide the desired welding temperature exactly/constantly with the Digital Adjustable and Temperature Controlled Thermostat Circuit. These machines do not have Vacuum and Gas facilities.

The MAP25 series is a product designed and developed for beginner or medium capacity manufacturers. Its stainless steel body is extremely robust and the machine s settings are not impaired during displacements. Since the seealing pool is cast, it is very durable and long-lasting. The MAP25 electrical system provides trouble-free service as it is protected against water, humidity and external influences. It is very easy to maintain and clean. It fits comfortably in any production environment. Thanks to its touch screen, all steps of the packaging process can be easily controlled and possible error messages are displayed on the screen. Processes can be adjusted in accordance with all kinds of plates and films. With 99 program memories, it is possible to quickly switch to different production models. Gradual vacuum can be applied thanks to the specially designed ZERO2XYGEN software. With the molds that can be easily changed in a short time, different types of product packaging can be made in the same machine. MAP25E (Wide) The standard MAP25 structure, volume, mold dimensions have been expanded for large packages except for general use. This width is redesigned according to your packaging needs and our machines are produced in accordance with your needs. MAP25E-XL (Large Packages) Specially designed for your non-standard large and heavy MAP packaging needs. Although its basic functions are like the MAP25 series, a number of different engineering applications have been made for large and heavy packaging. The weld pool is washable. It is ideal for product packaging that is spilled, odorous, oily and polluting the environment. MAP25DS (Double Station) If the standard MAP25 does not meet your production capacity, you can increase your production capacity with the MAP25DS designed by placing two stations on a single body. MAP25 Skin It is a packaging method that provides an effective presentation on the shelves by covering the product with a film like a second skin. In SKIN packaging technology, the top film sticks to the plate from the point where the product ends and ensures a long shelf life without deteriorating the shape and position of the product. The mold structure of the machine, the quality of the tray used, the top film used and the closing technique are different.

autoMAP series are machine systems that can meet all your packaging needs with fully automatic systems. The production lines cover all stages, starting from tray feeding, product filling, weighing, sorting, MAP sealing, labeling, collection and stacking. Its body is completely made of AISI304 stainless steel. The machine is very easy to use, maintain and clean. It is suitable for the use of single and multi-compartment trays. With the special ZERO2XYGEN software, gradual vacuum processes can be easily applied. Molds can be easily changed by trained personnel. It is fully compatible with all kinds of packaging system accessories. Multi-Function Control System With its touch screen, all stages of production and possible error messages are instantly displayed on the screen. All processes can be adjusted in accordance with all kinds of trays and films. With the multi-program memory, it is possible to easily switch to different production models. The automation unit, which monitors and controls all kinds of production lines, immediately warns about possible errors, misuses and plumbing malfunctions and protects the system. The operation of the accessories placed on the line can be done from the autoMAP control panel. System controls can be made by accessing all autoMAP series machines over the internet. autoMAP100Mini It is a useful model designed for manufacturers with limited working space. It includes all the features of the autoMAP series. It provides great convenience in terms of both budget and settlement. autoMAP100E (Wide) The volume and mold dimensions of the standard autoMAP100 structure have been expanded for large packages other than general use. Machine dimensions, carriers and operating structure are redesigned according to your packaging needs and produced in sizes suitable for demand. autoMap200E (Wide) The 200E model has been designed by expanding the standard autoMAP200 structure, volume and mold dimensions for large packages outside of general use. Machine dimensions, carriers and operating structure are redesigned according to your packaging needs and produced in sizes suitable for demand. EcoSEAL100Mini It is suitable for attaching all kinds of accessories like all fully automatic machine models. Automatic Tray Feeding, Automatic Weighing and Filling, UV Disinfection, Metal Detector, Printer, Barcode Applicator etc. All packaging line accessories are automatically operated within the EcoSEAL 100Mini without any problems. It is the most suitable solution for your food/medical packaging that does not require vacuum and gas. autoMAP MD250 These are our fully automatic MAP packaging lines that can fully meet your need for high-capacity mass production in MAP packaging. Operation starts from tray feeding, covers all stages such as filling, weighing, sorting, MAP sealing, labeling, collection and stacking of the product.

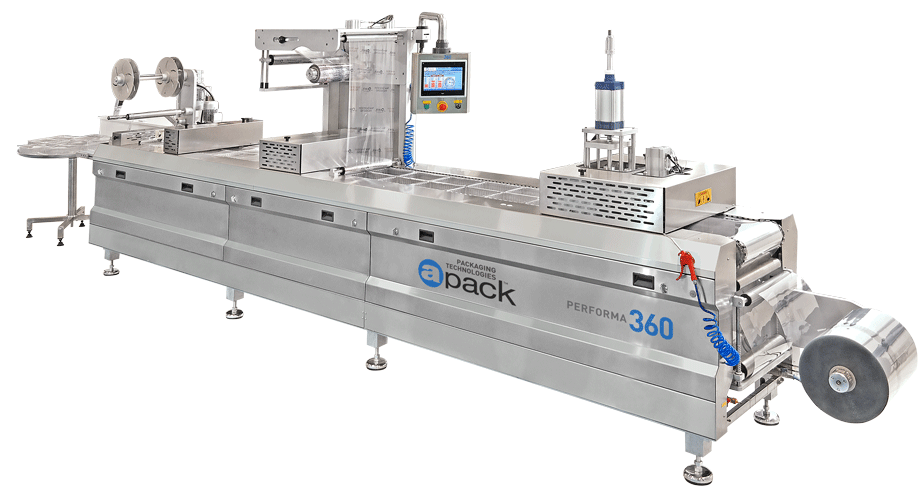

They are fully automatic machines that can shape the tray, fill and seal on one machine. It is suitable for FOOD and MEDICAL packaging. All stages of packaging such as tray production, automatic weighing, dosing, liquid / granule / powder filling unit, vibratory placement, film welding - cutting - labeling units, product sorting conveyor and product collection table can be operated on a single production line. Depending on the requested packaging structure, it can perform both VACUUM, MAP and SKIN applications. Double-acting form or reciprocating homogeneous form units can be applied to the production line. perFORMa series works with all kinds of upper and lower film types. It can produce economical packaging in high capacities by using single or multi-layer / laminated / foam films. With the special ZERO2XYGEN software, gradual vacuum processes can be easily applied. It is fully compatible with all kinds of packaging system accessories. All kinds of packaging molds such as square, triangle, round, rectangular, single chamber, multi chamber can be applied. Easy and safe use Thanks to the touch control screen, every step of the mold and packaging process can be easily controlled. The automation unit, which monitors and controls all kinds of production lines, immediately warns about possible errors, misuses and plumbing malfunctions and protects the system. With the multi-program memory, it is possible to easily switch to different production models. System controls can be made by accessing all perFORMA series machines over the internet.

AutoSEAL series are machines that close PET/PE jar mouths in different mouth diameters and all sizes with fully automatic systems. It is known that ultrasonic welding systems have some disadvantages in food packaging. That s why we developed our AutoSEAL-JS230 model. In food packages closed with autoSEAL, none of the materials get mixed with the product. It can be used easily and safely in all kinds of acid and base environments (pickle, olive, etc.). While the jar is opened, the closure film does not break and spill into the product. Production lines start with stacking empty jars on conveyors. JS230 controls all stages of the product such as filling, weighing, sorting, welding closure, capping, labeling, collection and stacking of the product. However, some operations of the line (jar sorting - product filling - capping) can also be done by the personnel. The body of our machines is completely made of AISI304 stainless steel. Moving belts and moving elements are made of hygienic material. The machine is very easy to use, maintain and clean. Jar weld closure can be made in any width and size. Thanks to the touch screen of the AutoSEAL-JS230, every step of the packaging process can be easily controlled. The automation unit, which performs all kinds of monitoring and control of the production line, immediately warns about possible errors, misuse and installation failures and protects the system. Processes can be adjusted in accordance with all kinds of jars and films. APACK will help you meet your top film needs.

No represented companies found.

The company has no registered brand information.

TR

TR