| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ATHA MAKİNA A.Ş.

Atatürk Plastik OSB Mah. 6. Cadde No: 7 / Menemen / İZMİR / TÜRKİYE

|

Contact Info: +90 232 375 7422

|

Hall: 12

Stand: 1210B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Our Company ATHAPACK, is a leading Turkish manufacturer of vertical packaging machines, Doypack and horizontal packaging machines, combinational multi-head weighers, linear weighers, auger filling and volumetric dozing units, food processing machines, vertical and Z type bucket elevators, various conveyors and special projects. Our goal is to provide our customers with comprehensive projects, sales, manufacturing, supply, service, installation and commissioning of technologically advanced and efficient packaging machines and packaging lines. Our Vision Without compromising the ethical principles, our professional staffs, follow the scientific and technological development, focus on customer and employee satisfaction, service with international quality standards in the leading applications of this sector to become a global brand in the market.

The RAPID series, which works with the Continuous Motion system, reaches maximum speeds that can be reached using Servo-Motion technology. As Continuous Motion system works 30% - 50% faster than Intermittent motion system, they are more perefered. However, there are other benefits of this series, such as low film Speed, less film distortion, no damage to product, more smoother vertical sealing jaw. It is the most preferred series for chips and powder products due to these benefits. Thanks to the modular design of the RAPID Series, it can be upgraded at any time with accessories and devices to produce different bag styles and respond to the market needs. General Features Continuous Motion System All surfaces in contact with the product are AISI 304 stainless steel Nitrogen gas flushing system (option) Air conditioning on the control cabinet (option) Static Eliminator (option) Printer application (option) Vacuum application on drive belts (option) Automatic Film changeover (option) The parameters and settings are made easily from the 15 industrial PC All functions of the machine are controlled by the Motion Controller All main movements in the machine are carried out by independent Servo motors Works with and without photocell The sealings are provided by P.I.D Heat Control System With film adding Unit, bobbin replacement is easy With the Auto-Film Centering System, the film is always centred Auto-Film Merkezleme Sistemi ile film sürekli eksende With the Auto-Film unwinding System, the reel is continuously opened at the same tension. When the film is finished, the machine is automatically stopped Any error occurs, the machine is automatically stopped and the errors will be displayed on the screen Packaging materials: Polypropylene, polyethylene, all laminated films, barrier film, water-soluble film Types of bags: pillow bag, gusseted bag, flat bottom bag, edge scratch bag and string bags Suitable for different types of filling systems: Volumetric & Auger filler, Multihead & Linear weighers and various liquid fillers CE standard

FOCUS series is designed for doypack packaging need, it can make standard doypack pouches, as well as with special additional functions like zipper, hanging hole, spout or special shapes. It also has big size and duplex series, which can meet packaging requirement of big volume and high speed. Stand-up pouch is the modern packing style, which makes your product attractive and prolongs its shelf-life. Thanks to Zipper application, stand-up pouch is the most reliable packing for dried fruits, frozen foods, juices, dairy products, salad dressing, soups, spices, washing and hygienic detergents etc. The machine s best advantage is its extreme flexibility. It can operate with multiheads and linear weighers, volumetric and auger fillers, fillers for liquid, paste, dry or powdered products including hot products. General Features All surfaces in contact with the product are AISI 304 stainless steel Zipper application (option) Punch hole or Euro hole application (option) Nitrogen gas flushing system (option) Air conditioning on the control cabinet (option) Static Eliminator (option) Printer application (option) Round Corner application (option) The parameters and settings are made easily from the 15 industrial PC Easy machine adjustment for change over A film reel auto-alignment shaft Auto-Film unwinding System, One set of bottom seal Unit An independent bag former Three sets of horizontal sealing unit Two set of vertical sealing unit Servo pouch puller Mechanical scissors Easy tearing notch cutter Set of vacuum bag opening device Automatic material-level control system A Photocell tracking control system A LCD touch-control operation system A PLC control system An automatic control system A product outlet system When the film is finished, the machine is automatically stopped Any error occurs, the machine is automatically stopped and the errors will be displayed on the screen Packaging materials: Polypropylene, polyethylene, all laminated films, barrier film, water-soluble film Types of bags: Doypack Bags with or without zipper Suitable for different types of filling systems: Volumetric & Auger filler, Multihead & Linear weighers and various liquid fillers CE standard

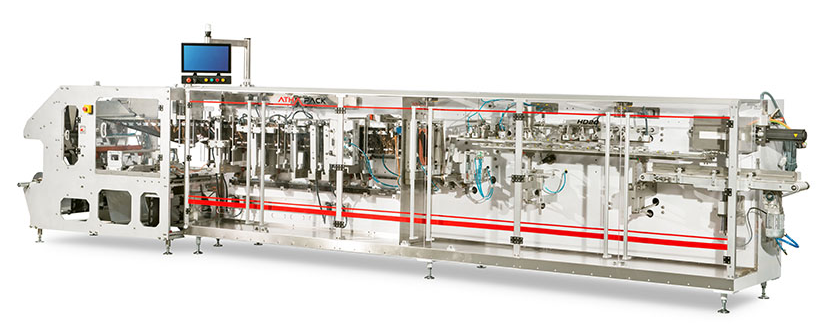

Packed products must, at some point, to unpacked again. With our innovation solutions to simplify this process, you can now decide how you want your products to appear on store shelves. Retail Ready Case Packing systems, which include applications such as tray, tray+lid as standard, are designed as Robotic or Cartesian according to the products. We have compact solutions for vertical and/or horizontal arrangement inside of the box.

No represented companies found.

- ATHAPACK

- SONOMEC

TR

TR