| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

APACK AMBALAJ MAKİNE SAN. VE TİC. LTD. ŞTİ.

Ferhatpaşa Mahallesi 22. Sokak No: 43 34888 / Ataşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 661 3371

|

Hall: 11

Stand: 1109B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

APACK was founded in 2004 and began producing its own food and medical packaging machines in 2014, offering cutting-edge packaging solutions to customers worldwide. Our machines meet international standards and are currently exported to over 60 countries. Starting with MAP25, we have expanded our product line to include 25 different models across 8 subcategories, all produced in our state-of-the-art facilities in Istanbul. Regardless of the model, we approach every machine with the same level of care, quality, and use of modern technologies. Our product range spans from practical desktop models to fully automated packaging machines. User-Friendly Solutions APACK machines are highly customizable to meet each customer s specific demands and needs. They are designed to be user-friendly, easy to clean, and easy to maintain. All machines are made of AISI304 stainless steel, following world standards. The automatic machines are controlled via touch screens and can also be remotely controlled through an internet connection. The APACK machines are also compatible with various Packaging Line Accessories, such as Tray Denester, Multihead Portioner, Weigher, liquid or solid Automatic Filler, Printer, Labeller, Conveyor, Metal Detector, UV Scanner, and Gas Mixers. Customers can also benefit from our Spare Parts, Technical Service, and machine use and maintenance training.

The EcoSEAL packaging machine with fully automated systems can meet all your packaging needs. It is designed for tight spaces and limited budgets, similar to the features of fully automated machines. The system is compatible with a range of auxiliary units, including tray feeding, filling, weighing, sorting, sealing, labeling, collecting and stacking equipment. The automation unit responsible for monitoring and inspecting all aspects of the production line will signal warnings in the event of any possible errors, misuse, or installation failures, thereby safeguarding the system. The machine accommodates single and multi-compartment trays and supports using various printed or unprinted multi-layer top films. Operating, maintaining, and cleaning the machine is simple, and trays can be filled with either hot or cold products. Additionally, the packaging process does not affect the quality of the product.

The AUTOMAP series of machines are complete and automated packaging systems that meet all your packaging requirements. These high-capacity autoMAP machines are particularly well-suited to the Food and Medical markets, where quality and precision are paramount. Additionally, these systems are designed to work seamlessly with other machines in your manufacturing facility, providing a cohesive and integrated packaging solution. In fully automated production lines, autoMAP packaging machines play a critical role by providing the ability to package products using various techniques, such as Modified Atmosphere Packaging (MAP) with vacuum and gas and thermal sealing applications. These versatile machines offer various packaging options for different product types and requirements. Our production line begins with tray feeding and manages every step of the packaging process, including filling, weighing, sorting, MAP sealing, labeling, collecting, and stacking. Depending on the investment budget, certain aspects of our machines, such as product filling, labeling, collecting, and sorting, can be carried out through fully automatic systems or manual operation. Gradual vacuum operations can be easily performed using the special ZERO2XYGEN software. The unit is simple to use, easy to maintain, and hygienically suitable for food production. Single or multi-compartment trays can be used while filling hot or cold products. We make sure packaging methods do not affect product characteristics. autoMAP series machines are designed to be customizable according to customer needs. Our autoMAP line-up includes 100E, 100Mini, 100MiniEXL, 200E, 200EXL, 300, and 400 with different functions, features, and capacities. We have designed and implemented specific liquid filling and automatic cap feeding units for aluminum tray packaging, primarily used in the military ration and ready-to-eat meals (MREs) with an extended shelf life.

These machines are fully automatic and can form, fill, and seal formed trays. Depending on the desired package type, they can perform VACUUM, MAP, and SKIN packaging and are suitable for food and medical packaging. perFORMA thermoforming machines are especially preferred in portion packaging, various cheese, fresh or processed meats, sliced salami, sausage, phyllo, ravioli, fish, and other types of seafood packaging. The machine is widely utilized in the medical sector for packaging medical consumables such as surgical gowns, gloves, IV tubing, syringes, needles, machine kits, dressing materials, test kits, etc. Typically, Tyvek-type medical paper sealing on soft bottom film is the preferred method in medical packaging.Online access allows for system controls to be managed for all perFORMA series machines. It holds international certification for both the food and medical industries. Packaging can be fully automated using these machines, from tray production to final product collection. It is also highly flexible and can be easily integrated with different packaging system accessories and machines in the production line. Customization options for the machine elements are available to match the production area and customer s requirements. Various packaging molds can be used, including square, triangle, round, and rectangular shapes. The machines can handle hot and cold filling of products, and packaging methods do not affect the product. Additionally, they can produce cost-effective packaging at high capacities using single or multi-layered, laminated, foam, or medical films. Gradual vacuum operations can be easily performed using the special ZERO2XYGEN software. The machine is easy to use, maintain, and clean. The tray forming unit is compatible with preheating/cooling with air or water / homogeneous or double-effect molding methods by the packaging material. perFORMa series works with all kinds of top and bottom web films.Top-notch and long-lasting industrial systems are manufactured from AISI304 stainless steel and 5000-7000 series aluminum, ensuring durability and quality. The mobile components and conveyor belts are fashioned from sanitary materials.

The MAP25 series stands out as the most proficient and dependable among its counterparts. It boasts exceptional durability and does not tend to malfunction, thus preventing operational issues. Moreover, this unit is designed to fit compact production spaces and can be effortlessly cleaned, serviced, and operated. Notably, all models in this series are suitable for packaging food and medical products. Designed and engineered for small to medium-sized manufacturers, the MAP25 series is a remarkable innovation. It has an impressive production capacity of up to 5000 packages per shift and can handle solid and liquid products. The unit supports various package shapes, including square, triangular, round, rectangular, and single or multi-compartment formats. Moreover, the products can be filled at hot or cold temperatures, and the packaging method has no adverse effects on the product. Quality It is the very first model produced by APACK. The design and technology of the unit are continuously refined to enhance its performance. The stainless steel body bolsters its robustness, and the settings remain unchanged during relocation. The machine s body is crafted from AISI304 stainless steel, while its molds are made from 5000-7000 series aluminum. Industrial standards fabricate the unit to create a high-strength, durable casting sealing pool. Only premium-quality electrical, electronic, and pneumatic components are sourced from renowned global brands. Changeable Mold Set The changeable mold system enables quick and effortless modification, allowing the machine to produce various packaging types simultaneously. The unit can package products of diverse shapes and sizes, including squares, rounds, ellipses, and triangles. Furthermore, by adjusting the depth of the pool, the same product can be easily packed in various weights. Modern Packaging Techniques Our machines are compatible with modern packaging techniques, highly favored in the food and medical industries. The MAP25 machine can easily accommodate various packaging methods, including tray sealing, vacuum, gas flush, MAP, SKIN, and CARDBOARD types. Multi-Function Control System The touchscreen interface enables effortless monitoring and control of all packaging steps, displaying any potential error messages on the screen. The process can be customized to accommodate various tray and film types, and the unit features 99 program memories for quick transitions between different production models. Additionally, the special ZERO2XYGEN software enables gradual vacuum application. MAP25 has got Double Station and extended models (E-EXL) You can apply MAP-SKIN and CARDBOARD packaging technich with MAP25 models.

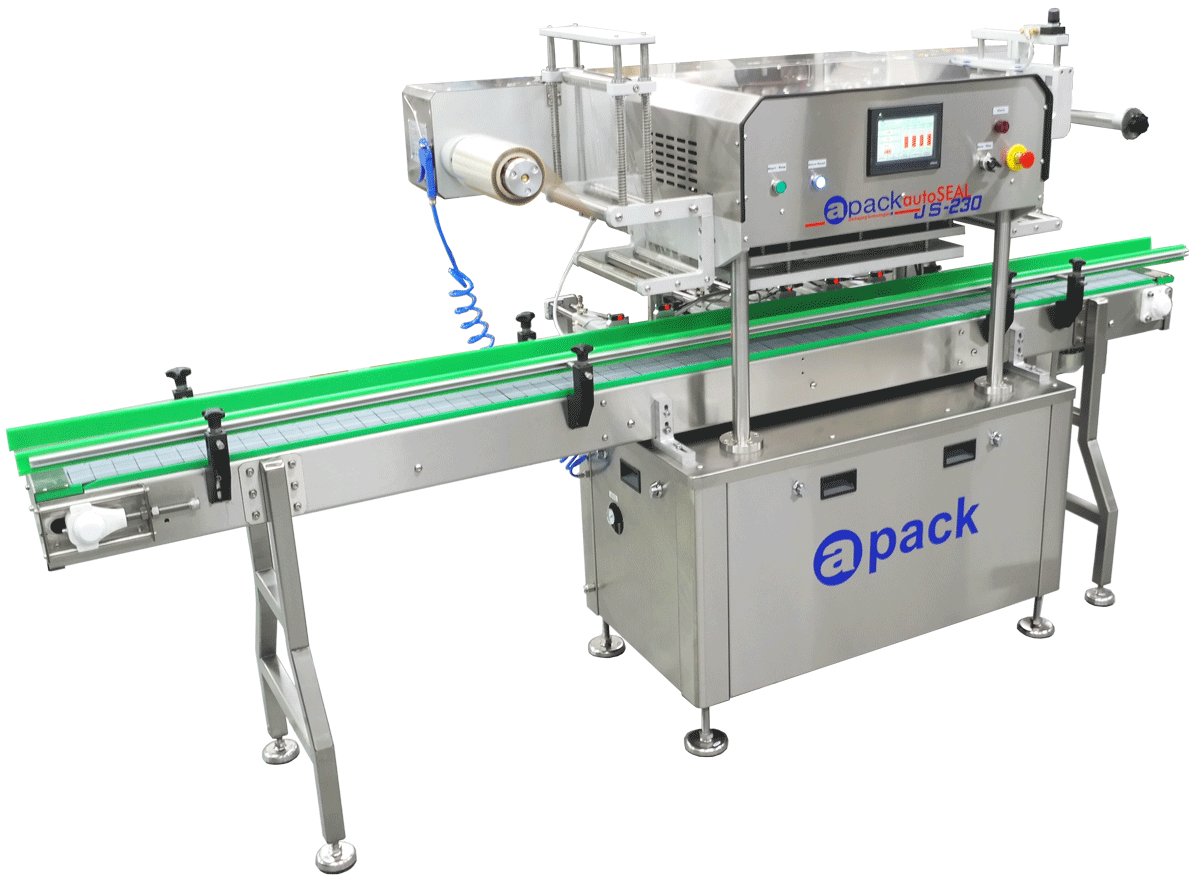

AutoSEAL-JS230 is a sealing machine designed for PET jars containing food or chemical products. It is particularly suited for sealing acidic products, including pickles, olives, and brine, as well as for sealing liquid or granular chemical products. AutoSEAL-JS230 machines are fully automated and use heat treatment to seal PET jars mouth of various sizes with a multi-layer top film, making them suitable for products that do not require a vacuum. These machines are specifically designed for use in small production areas. Unlike ultrasonic sealing systems used in food packaging, the sealing film on jars sealed with the AutoSEAL-JS230 does not break or fall into the product when opened. This model is a reliable, user-friendly solution for packaging pickle, olive, and brine products. The production line starts with stacking empty jars on conveyors and can cover all stages of product filling, weighing, sorting, sealing, capping, labeling, collection, and stacking. The touch screen on the AutoSEAL-JS230 controls all operations, while the PLC control module instantly notifies of possible errors, misuse, or installation failures and protects the system.

No represented companies found.

The company has no registered brand information.

TR

TR