| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AYGENTEKS İÇ VE DIŞ TİC. SAN. A.Ş.

YEŞİLKÖY MAH. ATATÜRK CAD. DÜNYA TICARET MERKEZI NO: 10 /1 İÇ KAPI NO: 439 BAKIRKÖY / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 465 7321

|

Hall: 1A

Stand: 17B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Aygenteks, a family company, was founded in 1973 by Metin Cenap Aygen. With the establishment of the company, the first main target was to provide consultancy services to textile yarn. In 1988-1989, Aygenteks decided to change its marketing company structure and activities. Since 1990, with the second generation management, it has developed from a service policy consultancy to a quality control and laboratory testing devices representation and distributorship for textile companies. Accordingly, spare parts, consumables stock and after-sales technical service programs were structured. In addition to the customer-oriented service provided for years, the company received the right to provide equipment, training and service to the quality control and laboratories of the textile industry abroad in 2006. To reveal the experience, knowledge and trust gained from the past of Aygenteks, which received new distributorships and representations in line with this decision; It has become a company that produces solutions for laboratory testing devices in Technical Textiles, Automotive, Defense Industry, Aviation Industry, White Goods, Packaging, Food Packaging, Medical Packaging, Paper-Cardboard, Food Texture, Plastic, Rubber, Leather and similar sectors.

The model 49-56 Digital Micrometer combines unmatched accuracy and resolution, a modern contemporary look with a robust mechanical design and new improved electronics, including a digital linear encoder. The unit has a measurement range of 0 10.0000 mm (0 10,000.0 um), 0 394.000 mil. Designed for thickness measurements of sheet materials, the 49-56 can be configured to meet any ISO, ASTM, EDANA or other International specifications for paper thickness, corrugated, plastics, plastic film, tissue paper, nonwovens, textiles and other sheet-like substrates.

The Elmendorf Tear Tester is an automated tear tester equipped with an optical encoder for measuring the angular position of the pendulum during tearing and converting this measurement to tear units. A large, full-color touchscreen display with intuitive, easy-to-use software provides a revolutionary new approach to testing and data review. The Spencer Impact method is based on ASTM D 3420. An attachment to the Elmendorf Tear Tester is mounted on the top of the instrument and measures the puncture impact resistance of a plastic film sheet or other related sheet-like material. The fixture consists of a probe mounted onto the end of the Elmendorf pendulum and an air-operated clamp used to secure the film sample. The unit measures the resistance to impact/puncture as the probe penetrates a sheet of plastic film. Both Elmendorf Tear and Spencer Impact measurements can be performed on one instrument.

Crease and Board Stiffness testing is useful to industries of corrugated, carton board, paper, printing and packaging. The relationship between board stiffness and crease recovery (spring back) is an important factor in the performance of cartons on high speed packaging machines and in manual folding. It is crucial to have the creases in boards correct and uniform. The crease recovery (spring back) can result in forces, which distort the carton or cause stresses to be applied to closures, which reduce their effectiveness.

It can be used with a detachable Digital Force Meter or ELS end load cell on renewed dV Motor models. If desired, tests can be recorded using VectorProTM Lite or VectorProTM MT software by connecting to a computer.

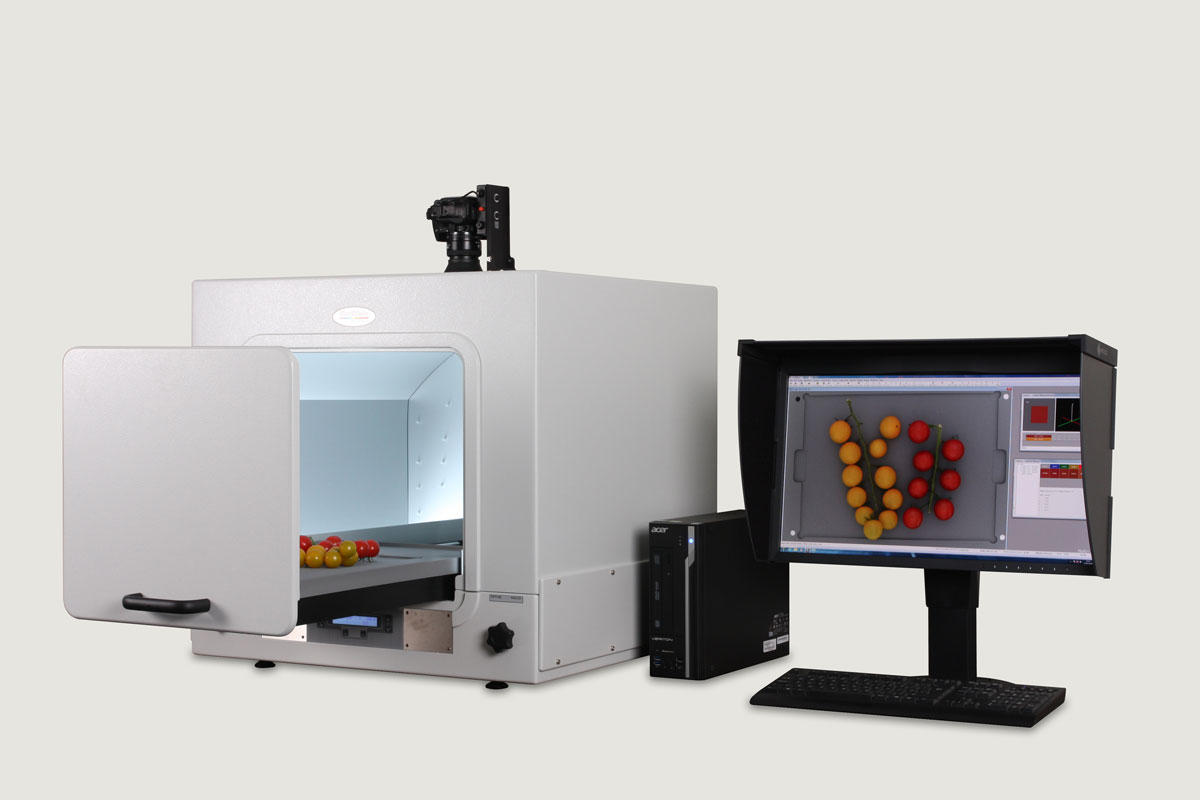

The DigiEye system captures the non-contact product image with very high sensitivity and resolution under indirect or direct lighting conditions, and offers color measurement and comparison on the image according to international standards. Color measurement and comparison can be made simultaneously on multiple sample images. It makes pass/fail and color direction evaluations according to standard formulas in color comparisons according to the given tolerances. It also makes very sensitive and repeatable measurements in the evaluation of general fastness tests (washing, acid sweat, alkaline sweat, wet dry rubbing, light).

The company has no registered brand information.

TR

TR