| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

BOSFORO MÜHENDİSLİK PROJE MAKİNA VE ENERJİ SAN. TİC. LTD. ŞTİ.

Ferhatpaşa Mahallesi 69. Sokak No: 44 / Ataşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 550 8070

|

Hall: 10

Stand: 1013A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

For 13 years, since the first day of its establishment, we have made it our duty to offer the most technological and ergonomic systems to our customers at the most affordable prices. In this way, we have had more than 2000 individual machines and lines for more than 1000 happy customers in a short time. It is not difficult to make a machine or a project for a customer once. The important thing is to be permanent in that customer and to be a permanent supplier. Unlike other competitors in the market, we succeeded. Our references have always been open and we have done more than one project with almost every client. We present our mission, which is to bring the most technological machines and systems to the customers in the most economical way, by producing machines and projects in our own production facility in Ataşehir or by combining advanced technology and patented products from Italy with our own engineering. We are at the disposal of our customers with our expert staff in Technical Service and our large stock of spare parts. We always satisfy our customers with the most economical prices in spare parts. Our vision is to be an important packaging machinery manufacturer and supplier in Türkiye and in the world. Our goal is to wave our flag in different geographies with patented products by doing R&D. We are always welcome to have a coffee at our Plaza and Production Facility and to show our machines in our Showroom. Best regards, Bosforo Mühendislik Proje Makina ve Enerji San.Tic.Ltd.Şti.

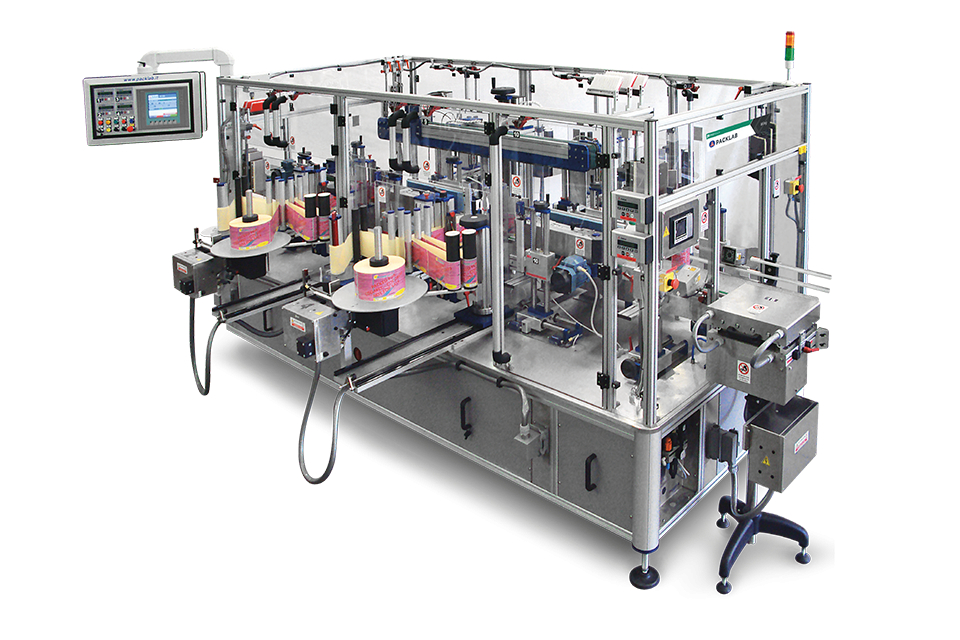

Pressure sensitive linear labeling machine, for speeds from 4,000 to 48,000 PpH, to apply partial body or wrap-around labels to cylindrical containers and partial front and back labels to shaped containers. Base with external labeling stations to give more accessibility to the operator both during the working phases and during the format changeover. Available in NON-STOP version to avoid production downtime.

Each model is designed to be highly efficient at wrapping all kinds of products, including those that are unstable, very light or easily crushed. It operates using a rotating arm which wraps around the product producing a highly secure and stable fully loaded pallet. To achieve this the pallet is wrapped whilst it is stationary. The design of the strong steel frame guarantees a long working life and the clever way the cabling is routed through the inside the frame, guarantees it to be a robust machine which consequently presents a very low risk for accidental damage. This adds to the already high level of reliability the revolution is known for, it also minimises the potential for interruptions to the production process. The machine is designed to be extremely compact and this results in a very small footprint on the factory floor.

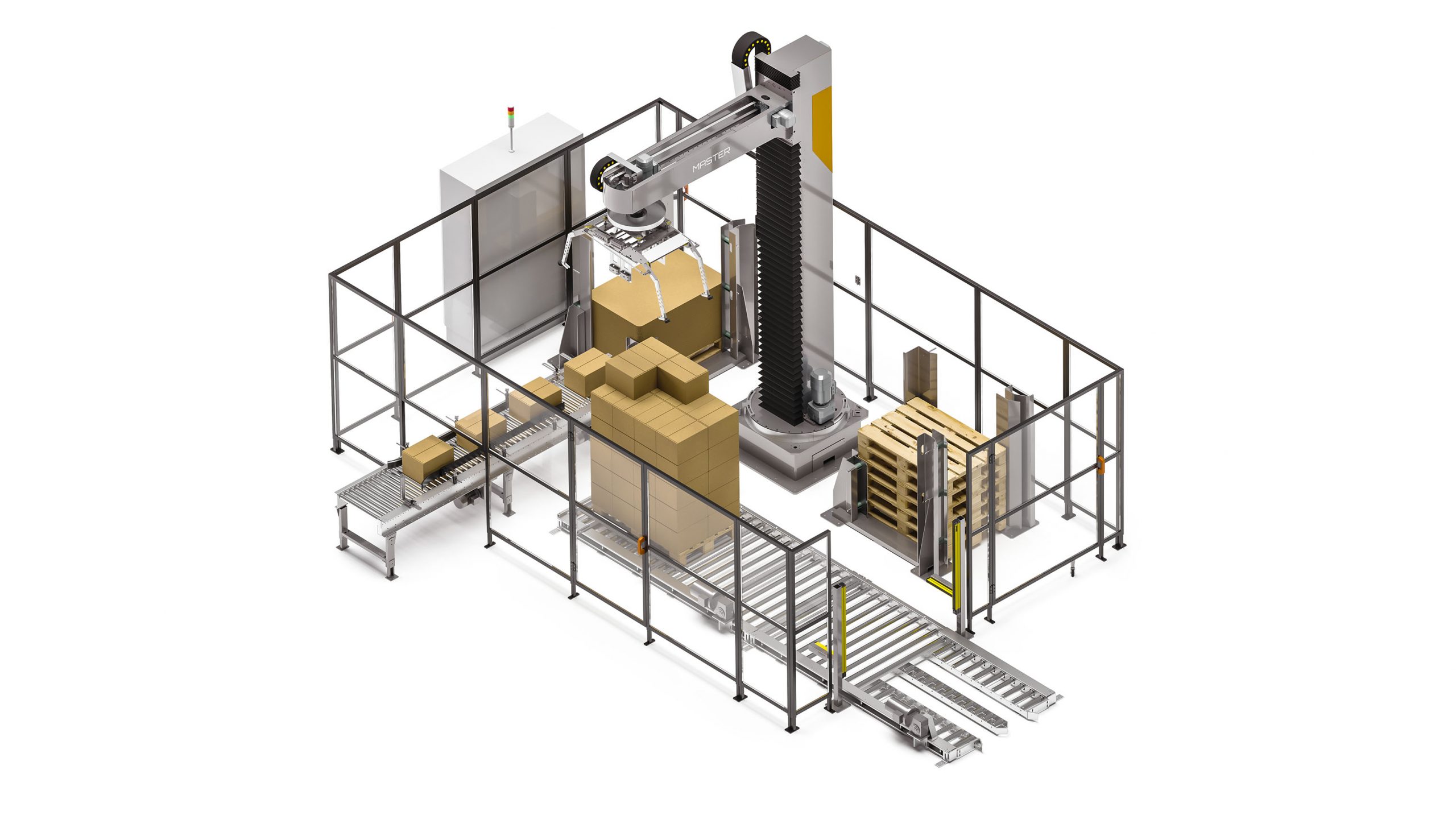

The MASTER500 is a palletizing robot with a single column rotating structure. It is equipped with two linear axes and two circular axes interpolated between them, and the main movements are realized by asynchronous motors coupled to high quality gearboxes. Thanks to a small footprint, this robot allows you to work on one or two lines at the same time, with single or multiple gripping head to guarantee the required production and satisfy the most varied applications. The robot is suitable for the palletization of products such as full cartons, bags, bundles. By means of a special gripping head, the product arriving from a feeding belt is taken and deposited on the pallet, according to the selected scheme. The machine is controlled by an industrial PLC, which is associated with the use of a Touch Screen,user managed operations by an user friendly HMI panel control.

F1000+GEM B52; The box maker takes the boxes from the side magazine (Case loader) and prepares them with the 4 bottom covers folded. The bottom covers are closed with adhesive tape (GEM B52) and sent to the filling point. This carton making machine assembles perfectly folded boxes even on lightweight cartons, thanks to the folding device specially designed for this machine. Any interference between the wings during folding is completely eliminated. Compact dimensions allow the machine to be incorporated into existing lines or installed in a limited space. GEM F470; Manually sized, automatic taping machine with lid closer. Automatically closes the top four flaps and seals American-style fixed format boxes with adhesive tape.

The one of Weightpack is a story that deserve to be told. Founded in 2002 by Carlo Corniani, worldwide recognized for having introduced, in 1979, the first net-weight filler with electronic control, the company has its roots in the early years of the last century. They ran the 20 s when Carlo s father creates the first family factory, designing and building trailers powered by hydraulic technology. The young Carlo grows following in the footsteps of his father, totally immersed in that exciting pioneering atmosphere, showing immediately a natural talent for mechanical in all its forms. The sixties see the beginning of Carlo Corniani s career in mechanical sector, as designer and manager. At the same time, to confirm his huge passion for wheels and gears, Carlo becomes a respected pilot in races for kart and cars, all over the country. In the following decade, he will create the second family factory, developing his pioneering talent that will bring him to file a vast number of patents in filling and packaging fields. Carlo s sons, Andrea and Gianguido, represent the third generation of Corniani family. They are currently involved in the management of Weightpack.

The company has no registered brand information.

TR

TR