| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GUANGZHOU INTERNET WOOD GLUE TRADE CO., LTD.

Room 1210, 268 East Huangpu Road, Huangpu District, Guangzhou / / / CHINA

|

Contact Info: +86 189 0238 4185

|

Hall: 12A

Stand: 1284H1

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

IWG Group is a leading hot melt adhesive manufacturer and solution provider in China. With a plant area of about 200,000 square meters and a world-leading R&D team, IWG Group s products comply with national environmental protection testing standards. IWG Group owns 3 factories and operates over 24 subsidiaries in China, as well as overseas branches in Southeast Asia, Europe, and the USA.

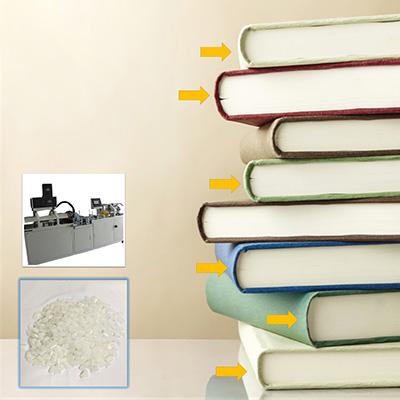

Book binding can use EVA hot melt adhesive or PUR hot melt adhesive for binding and bonding,use for making various books ,such as textbooks, ,picture books, brochures , notebooks ,dictionaries and magazines,etc. It is white flakes or granules with oil resistance and good adhesive Strength and good thermal viscosity, , suitable for high-speed product line with bookbinding about 5000 pcs books per hour . It has moderate opening time, good adhesion and fluidity, stable temperature resistance, no drawing and no empty glue during processing. To be competitive, the multiple steps required in binding a book must occur inexpensively and at a very high speed. As a result, hot melt adhesives have achieved a strong competitive position relative to adhesive emulsions, especially for long run production jobs. We offer bookbinding adhesives that give printing companies the ability to run up to 30% faster. The operations of assembling the book, trimming the back, applying hot melt glue, fixing the cover, and trimming the rest of the book are generally completed in a time span of less than 10 seconds.

Paper bag adhesive is divided into: hand bonding, side bonding and bottom bonding. hand bonding: It uses hot melt adhesive, which needs to be heated with a hot melt glue machine before it can be used. The launch of this machine meets the needs of automated production of paper bags. For paper materials with different surface treatments, the properties of the hot melt adhesive can be adjusted as required side bonding and bottom bonding: A water-based adhesive is used, which is made of a film-forming material that can be dispersed or dissolved in water. With the characteristics of frost resistance and high temperature resistance, it is widely used in the production and printing of product paper bags, gift paper bag production and printing, packaging carton production and printing, etc.

Kraft paper bag is a packaging container made of composite materials or made of pure kraft paper, non-toxic, odorless, non-polluting, low-carbon and environmentally friendly, and meets environmental protection standards The kraft paper bag is based on all-wood pulp paper. The color is divided into white kraft paper and yellow kraft paper. A layer of PP film can be used on the paper to play a waterproof role. The strength of the bag can be made into one to six layers according to customer requirements. , printing and bag making integration. The opening and back cover methods are divided into heat sealing, paper sealing and paste bottom.

It uses a hot melt machine to melt the hot melt adhesive into a liquid, and then sends it to the surface of the carton through the throat and spray gun of the hot melt machine. The hot melt adhesive is bonded after cooling. It can meet the requirements of carton sealing and overcome the defects of traditional carton sealing. For ordinary carton forming and sealing: food box and case forming. Winlong hot melt adhesives are known for their high throughput and clean processing, reducing maintenance costs and downtime during packaging. Whether for pallet assembly, folding box sealing or wrapping around state-of-the-art adhesive formulations with low resource impact keep processing costs low.

Sticker glue, also known as adhesive or adhesive glue, is a type of substance designed to create a bond between two surfaces, allowing stickers to adhere to various materials. Sticker glues are formulated to provide a secure and lasting attachment while offering ease of use and sometimes the ability to be removed without leaving residue. Here are some key characteristics and uses of sticker glue: Adhesion: Sticker glues are known for their ability to create a strong bond between the back of a sticker and the surface it is applied to. This ensures that the sticker stays in place over time. Versatility: Sticker glue is often designed to work on a variety of surfaces, including paper, plastic, glass, metal, and more. This versatility makes it suitable for a wide range of creative projects. Removability: Depending on the formulation, some sticker glues allow for easy removal without damaging the surface or leaving sticky residue behind. This feature is particularly useful when repositioning or replacing stickers. Application: Sticker glues typically come in various forms, such as liquid, gel, or solid sticks, making them easy to apply to the back of stickers. The application method may vary depending on the specific product.

It s formulated for tetrapak straw attachment with good pot stability and very low odor. Our adhesives can tolerate low temperature storages without having straws come off and keep good appearances of finished products. In addition, our adhesives can work in 140℃-160℃ without causing wire drawing problems. This better mileage property creates good values and benefits to our customers.

No represented companies found.

The company has no registered brand information.

TR

TR