| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HBK PACK OTOMATİK PAKETLEME VE AMBALAJLAMA MAKİNELERİ SAN. TİC. LTD. ŞTİ.

Orhangazi Mahallesi Isıso Sanayi Sitesi 4. Yol E Blok No: 30/19 / Esenyurt / İSTANBUL / TÜRKİYE

|

Contact Info: +90 536 632 2178

|

Hall: 12

Stand: 1234A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

We are proud to have achieved a first in the world with our experience in the sector since 1995. We would like to state that we are the only company in the packaging sector that produces flowpack (horizontal) and thermoform packaging systems together. Our main principle is to maximize the working capacity by minimizing the manpower with automation systems that offer technological solutions. Our fully automatic flowpack (horizontal), mobile jaw and thermoform machines are manufactured meticulously and completely in accordance with international standards, taking into account human health and safety.

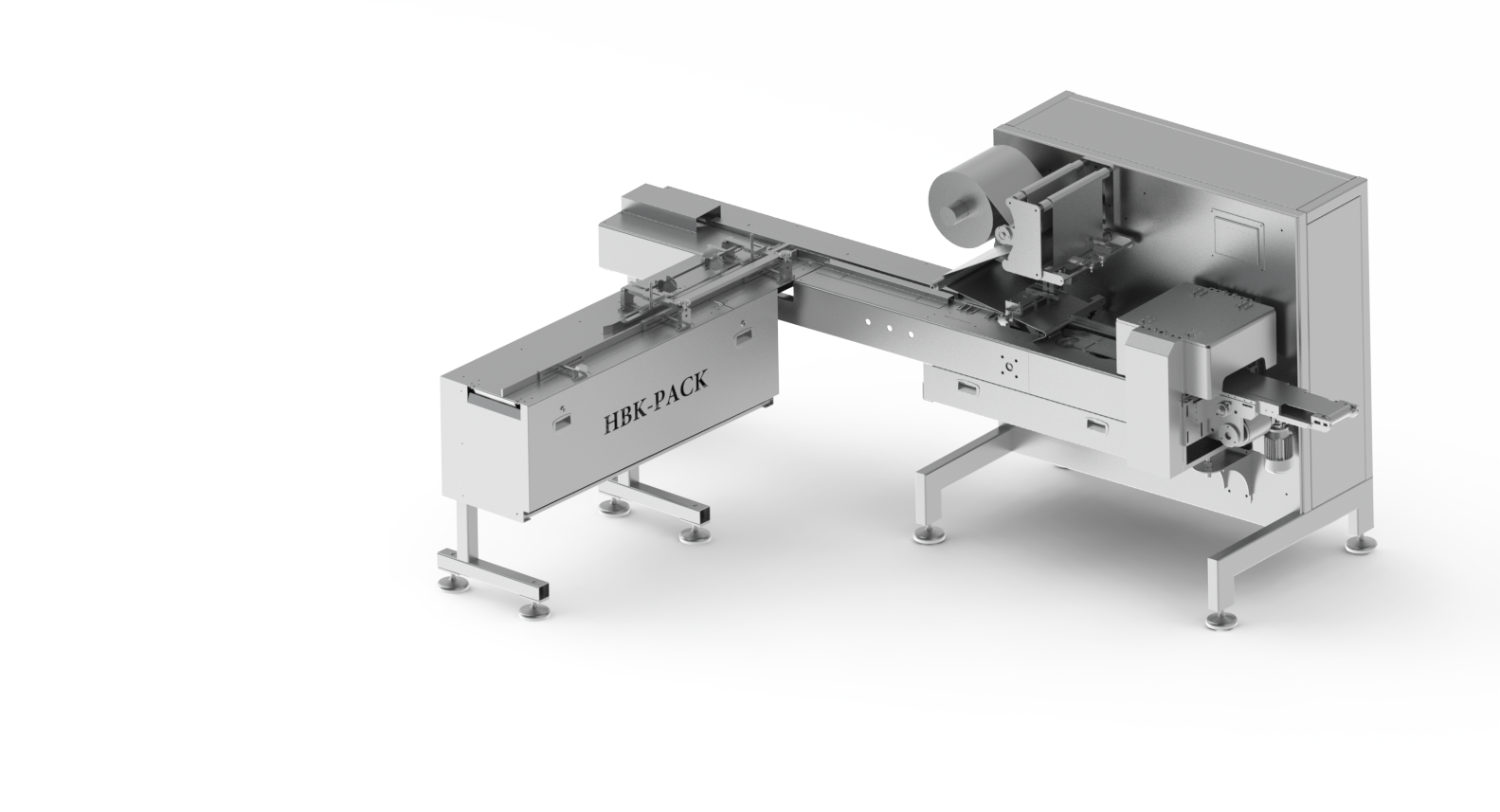

In the RK 200 90 ° Rotary Jaw Packaging model, the coil group is a manual system. The chassis structure and conveyor structure of the machine are designed and manufactured from AISI 304 stainless steel. Jaw, disc and carrier conveyor movements are provided by 4 separate servo controls, independent of each other. The recipe system for different products provides the operator with both quick product changes and ease of use. Products such as cakes, biscuits, bread, chocolate, wafers, halva, soap and croquant are packaged in the RK 200 90° Rotary Jaw model.

The RK 600 Rotary Jaw model uses 12 Kw (400 V, 50 60 Hz, 3 Phase) power consumption. Jaw, disc, coil and carrier conveyor movements are provided by 4 separate servo controls, independent of each other. Access and control is via the touch panel, and all necessary settings can be made via the panel. It provides packaging tension control at high speeds with a separate servo motor and electronic dancer belonging to the bobbin group. It has hot and cold bonding properties. In our RK 600 Rotary Jaw machine, the in-line feeding band; Thanks to its vacuum and cooling based feature, product flow stability is ensured. With its strong chassis, speed and efficiency for many years are among the most important features of the machine. The chassis structure and conveyor structure of the machine are designed and manufactured from AISI 304 stainless steel.

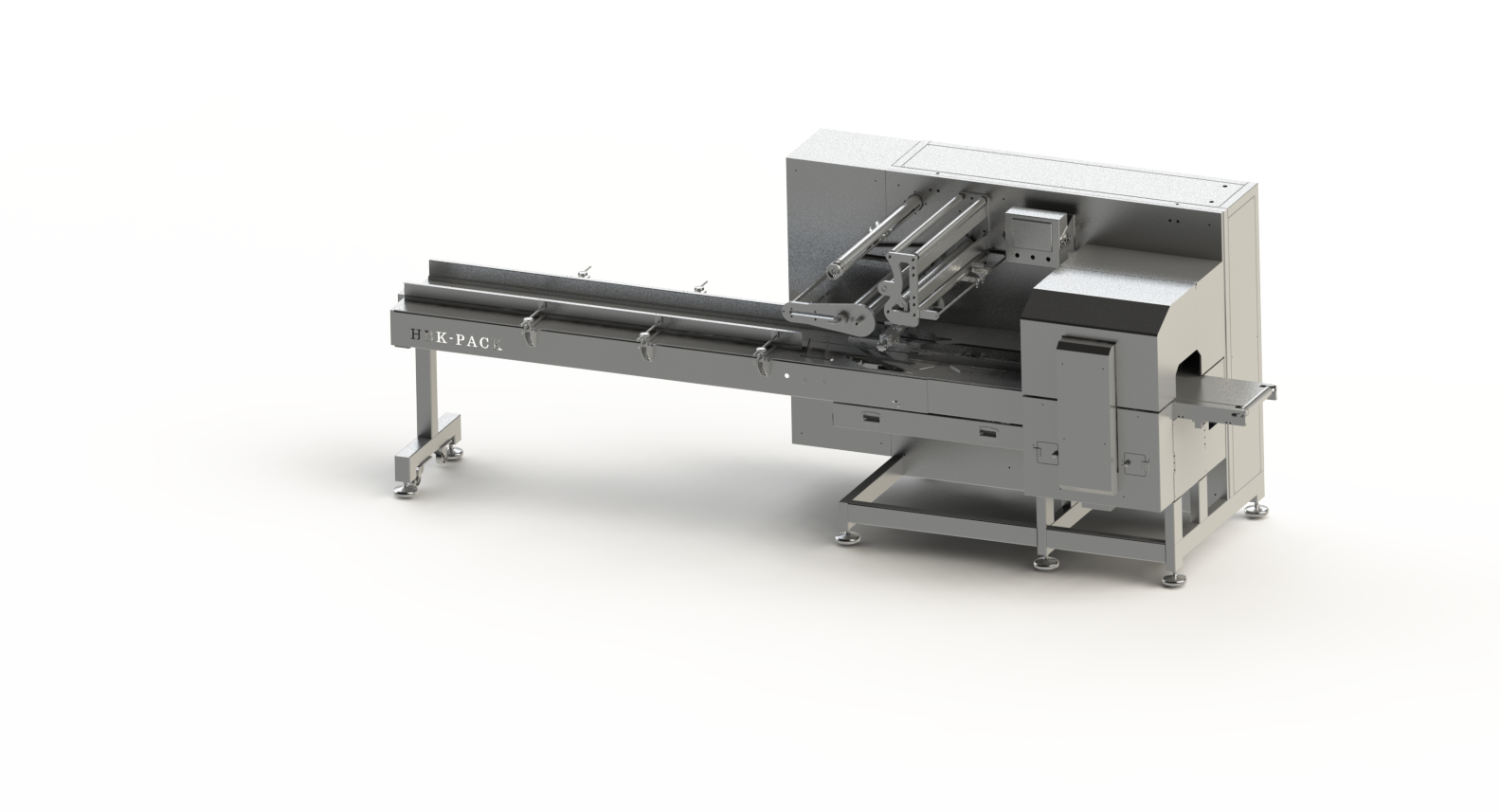

In the MJ 90 Mobile Jaw Packaging model, the bobbin group is a manual system. The chassis structure and conveyor structure of the machine are designed and manufactured from AISI 304 stainless steel. MJ 90 Mobile Jaw packaging model operates at a speed of 40/65 packages/minute depending on the product type and size, with a photocell spacing of max. 150 mm and a single product in the package. Jaw, disc and carrier conveyor movements are provided by 3 separate servo controls, independent of each other. In the eccentric jaw group, the blade system is mechanical, providing speed and high capacity. The recipe system for different products in our MJ 90 Mobile Jaw machine provides the operator with both quick product changes and ease of use.

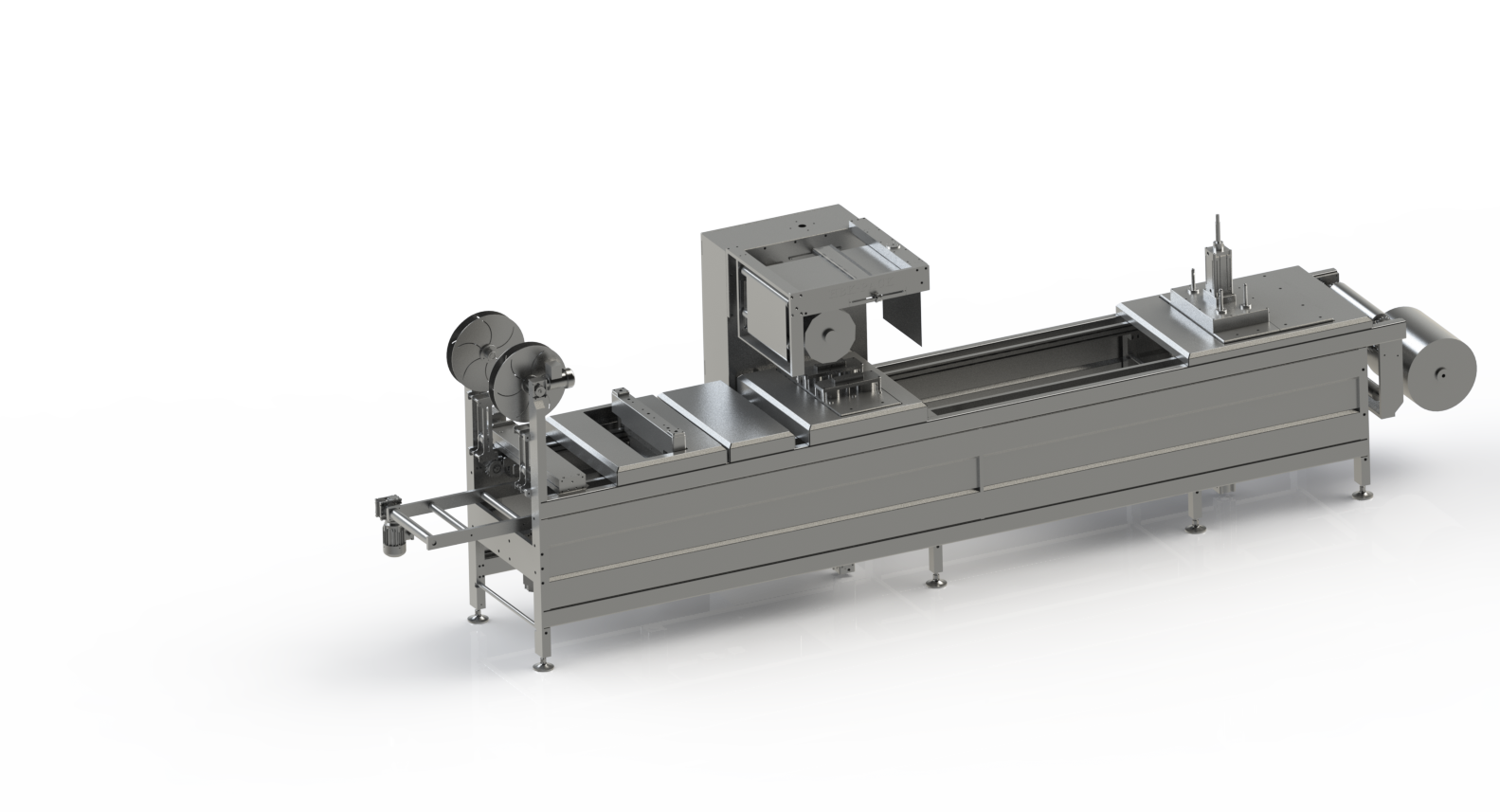

In the HF / 500 Chain Thermoforming model, the advancement system is servo motor controlled. All groups of our machine are produced from stainless quality AISI 304 material. Photocell system is available for printed top film applications. The molds that shape the product and are used in the bonding process can be easily changed. Automatic vacuum test control system is available. There is a special water retaining filter for pickled products. There is a brush type automatic chain lubrication system. The blade structure is stainless and long-lasting. Automatic filling option is applied depending on the product. Suitable for all kinds of special applications and shaped cuts. The world s highest quality materials are used in pneumatic lines. It provides different container shapes and combinations. All equipment used in the HF/500 Chain Thermoforming model complies with European standards.

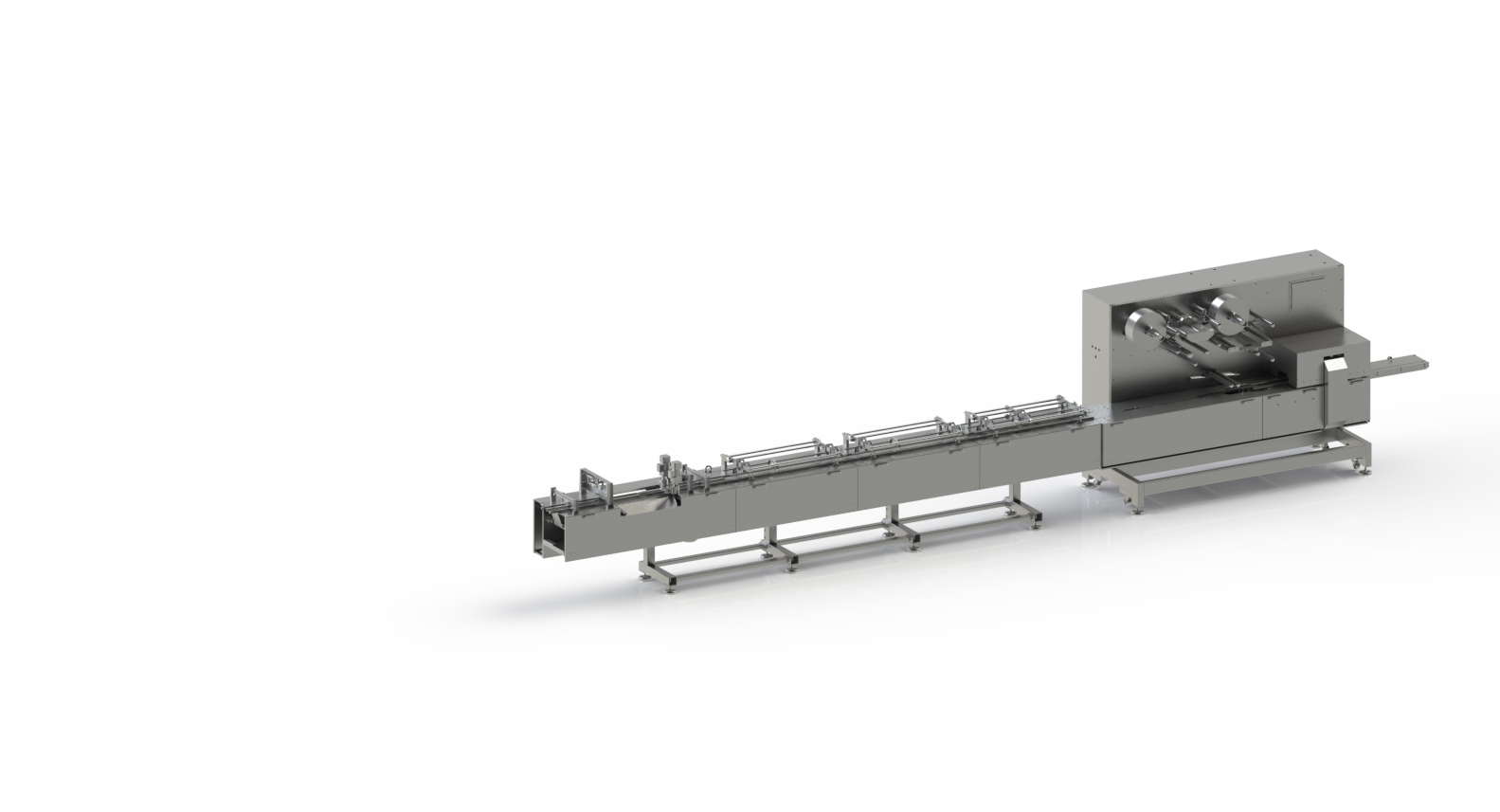

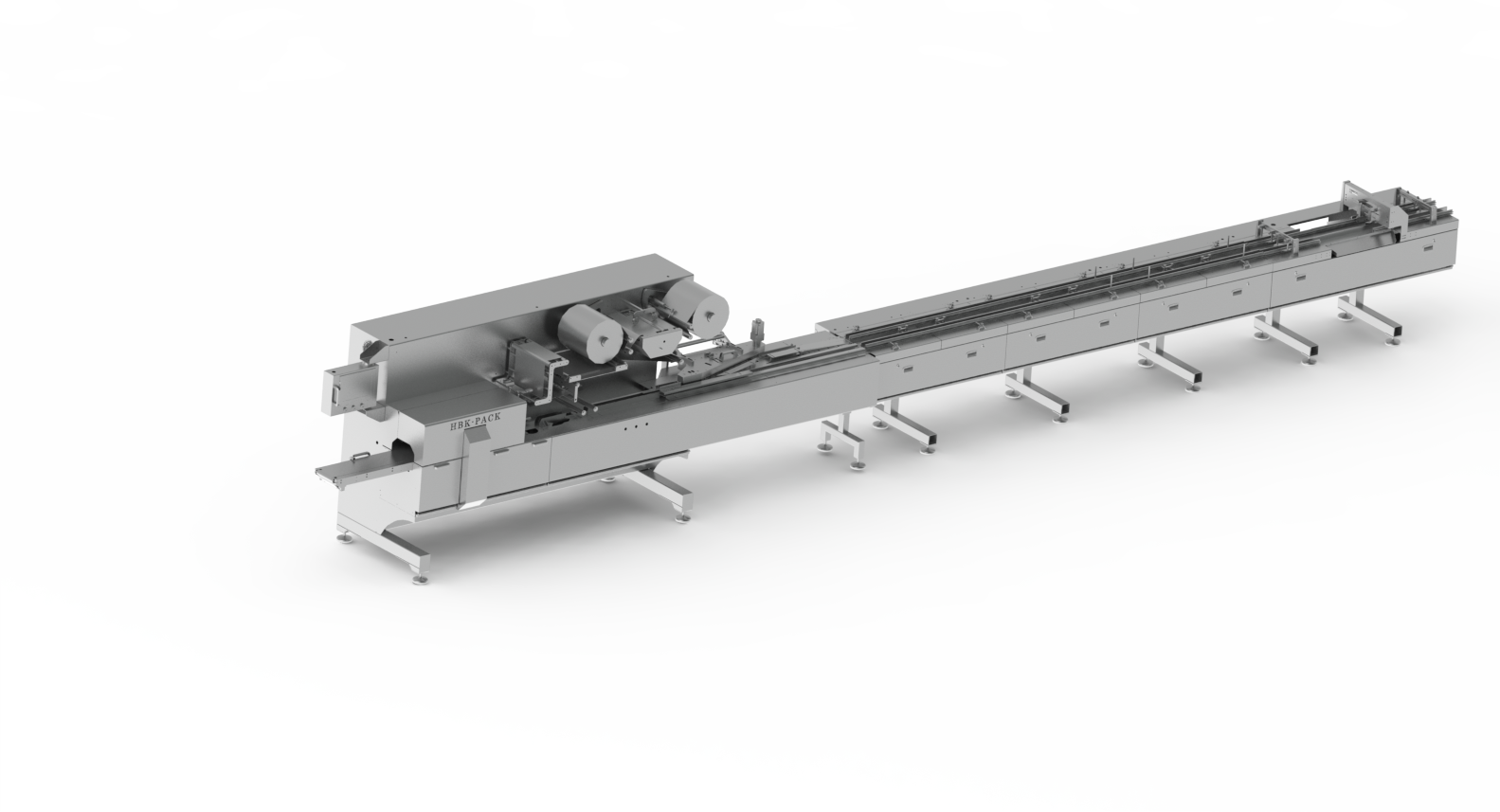

The DR 300 Twinline model uses 25 Kw (400 V, 50 60 Hz, 3 Phase) power consumption. It is specially designed with a strong body structure for high capacity based products. In-line feeding belt; Product flow stability is ensured thanks to its vacuum and cooling based feature. Therefore, the machine achieves trouble-free operating performance at high speeds. The DR 300 Twinline model is designed for easy access via the screen, as well as making all settings and applications for production via the screen. It provides packaging tension control at high speeds with a separate servo motor and electronic dancer belonging to the bobbin group. The chassis structure and conveyor structure of the machine are designed and manufactured from AISI 304 stainless steel. Our DR 300 Twinline machine has all servo motors with robust structure and low inertia dynamics. It provides short product transitions thanks to narrow turning belts. Provides product flow stability with its vacuum feature.

No represented companies found.

The company has no registered brand information.

TR

TR