| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KULP MAKİNE SAN. VE TİC. LTD. ŞTİ.

YUNUS EMRE MAH. İSKENDERPAŞA CAD. NO: 29/2 34791 / SANCAKTEPE / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 641 2183

Web: https://kulp.com.tr/

|

Hall: 11

Stand: 1111B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

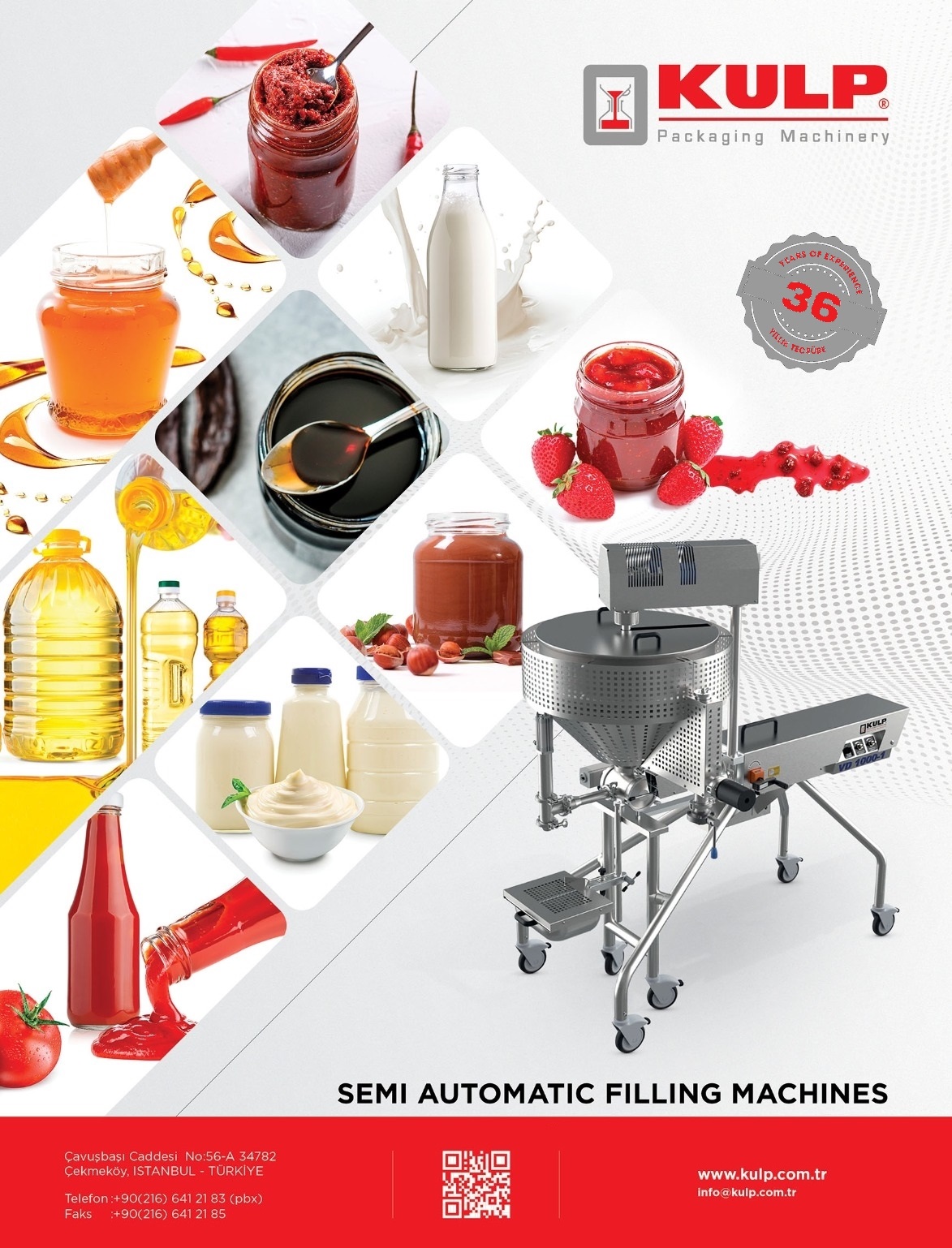

With short service time in spare parts supply thanks to its rich stocks, the company also presents solutions for its customers in after-sales process, and for continues development strengthens in R&D activities with each passing day. KULP® provides specially designed and manufactured long-life packaging machines with professional after sales service, KULP continues to lead the way with a desire for handing down its position gained with its - around- 1500 currently working machines domestically and abroad and contributes to development of the sector without compromising with quality. Today, KULP® continues increasing its presence on the international scene, starting with the Netherlands in 1997, the spreading to 7 continents either directly or through authorized sales agents in Germany, Belgium, Greece, Australia, Italy, United Kingdom, United States, India, Russia, Mexico, Colombia, and many up-coming reselling points in order to shorten the distance with the final customer.

- This is a volumetric filling machine that works with FESTO pneumatic system. - Easy to adjust and record the filling range by the numerator and the hand wheels. - It primes the product from its 80 liters 316 L seamless stainless steel hopper. - High surface smoothness and argon arc welding technology prevents contamination. - The seals are manufactured from teflon, viton or polyethylene according to the product to be filled. - The parts on the machine are connected by tri clamps. - The nozzle, the main valve and the filling piston are designed for an easy-cleaning .They can be dismantled easily without using any tool. - Interchangeable nozzles are available according the product, either it s liquid, viscous or particulated. - There is a heigth adjustable platform on the filler to place the packages during the filling process. OPERATING TEMPERATURE : From +5 ºC to +85 ºC with standard sealings. Above 90 ºC with special sealing.

· VOLUMETRIC FILLING SYSTEM AND NOZZLES CONTROLLED BY SERVOMOTORS OR PNEUMATIC SYSTEM · LIQUIDS, SEMI LIQUIDS, VISCOUS & PRODUCTS WITH PARTICLES · CAPACITY: 2000 - 3200 PACKAGES PER HOUR · FILLING ACCURACY: ± 1% . ANTI DROPPING SYSTEM ON THE FILLING NOZZLES · VARIOUS PACKAGING SIZES AND SHAPES · HOT AND COLD FILLING . COMPATIBLE WITH THE FOOD HYGIENE STANDARDS - Primes the product from a 100 liters hopper with an automatic level control system. - The level control system is synchronized with the transfer pump to start or stop. - All the parts including the main valve and the nozzles are connected by tri-clamps for easy disassembling for the cleaning process. - The volume adjustment can be done through the touch screen - There are four interchangeable filling nozzles that are designed for liquids and viscous products, with an anti dropping system. - Adjustable speed diving nozzle for foamy products. - Lighted cabin with 10mm poly carbon covers and security switches on the doors. - No container-No fill System. - User-friendly touch screen interface available in different languages. - 3 meters conveyer with adjustable side rails for various sizes of packages. - The working system is pneumatic and electronic. It operates with 6 bars of compressed air. - The consumption of air is 600 lt/minute when it s performing with the maximum volume and the maximum speed. - The electrical connection is three-phase (380v / 50-60 Hz) - Optional C.I.P. suitable cleaning system. - Optional Double Jacketed Hopper. - Optional Agitator. - Optional Filling Piston Back Side Cleaning System.

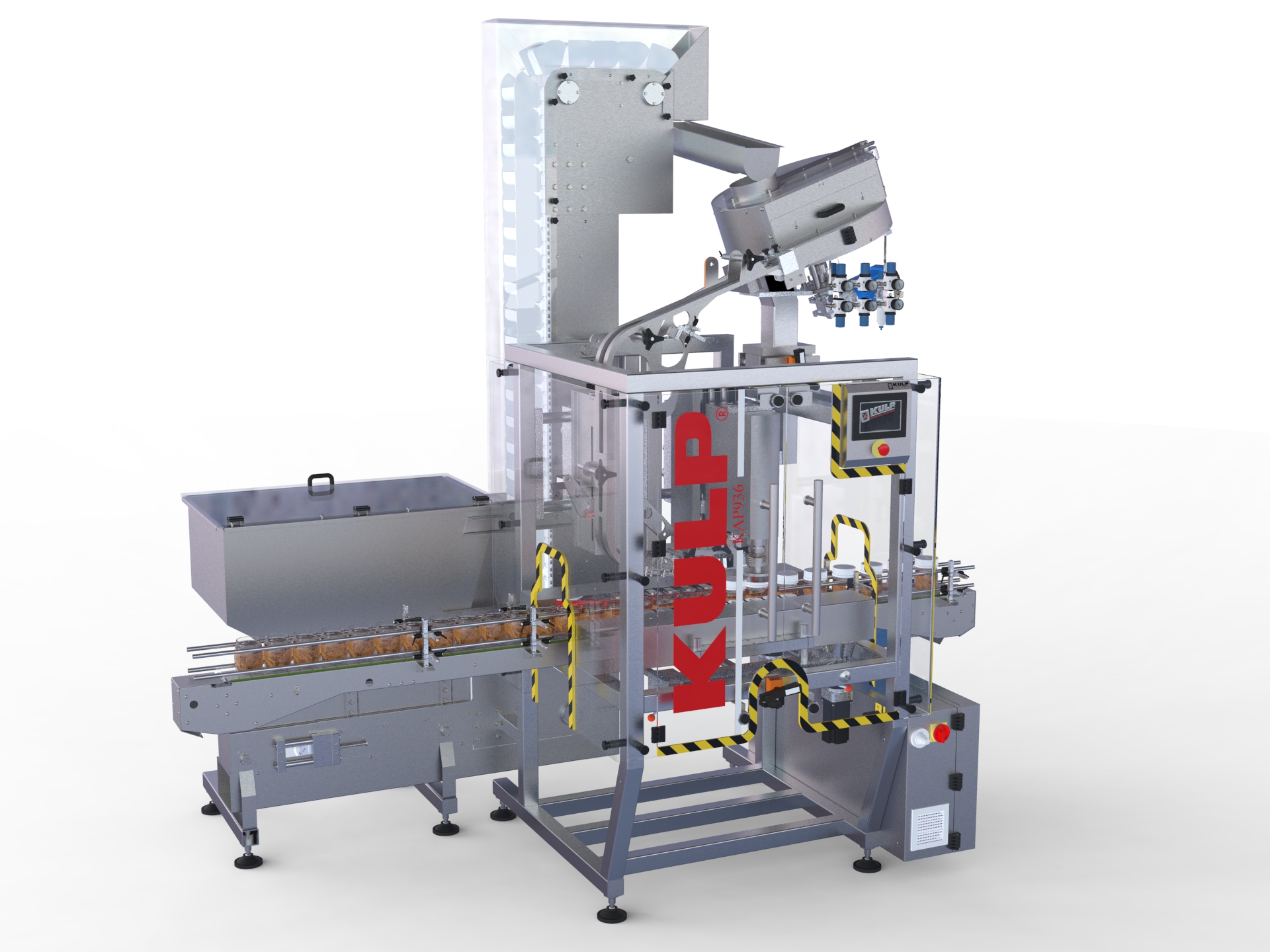

. SUITABLE CAPS : - Metal Twist-Off Caps - Plastic Screw Caps - Metal Screw Caps . CAPACITY: 3600 Packages/Hour . IDEAL FOR DIFFERENT SIZES OF CAPS - KULP KAP 936 Automatic Capping System is a compact solution which is capable of closing several types of caps. - It includes an integrated cap elevator to feed the caps to the cap sorting system continuously. - The sorting system is a mechanical sorter that enables to sort different types of caps and allows a quick change from one cap to another. - The sorting system distributes the caps to the cap chute and dispensing blade in the correct position. - Each cap chute and dispensing blade is designed for a specific size of cap with quick connections that enables users to adjust the capping machine easily from one cap dimension to another. - The capping head is driven by a step motor with an adjustable capping torque. - The capping head has a special plastic mould that is designed according to the different dimension of caps that prevents the damage of the caps that can be caused by friction. - All the mechanical adjustements according to the height of the packages (sorter, cap chute and dispensing blade) are done by the help of the handwheel and the numerator. - Runs on round, oval, square and rectangular containers without any change parts. - Superior stability of the containers during the cap tightening process thanks to the belt system, especially for high and soft containers. - The convoyer siderails can be easily adjusted according to the width of the packages. - User friendly touch screen interface available in different languages. - 3 meter speed adjustable conveyor line. - Works with 380 volts / 50-60 Hz electrical power. - Heavy Duty Stainless Steel Frame. - Lighted cabin with 10mm polycharbon covers and security switches on the doors.

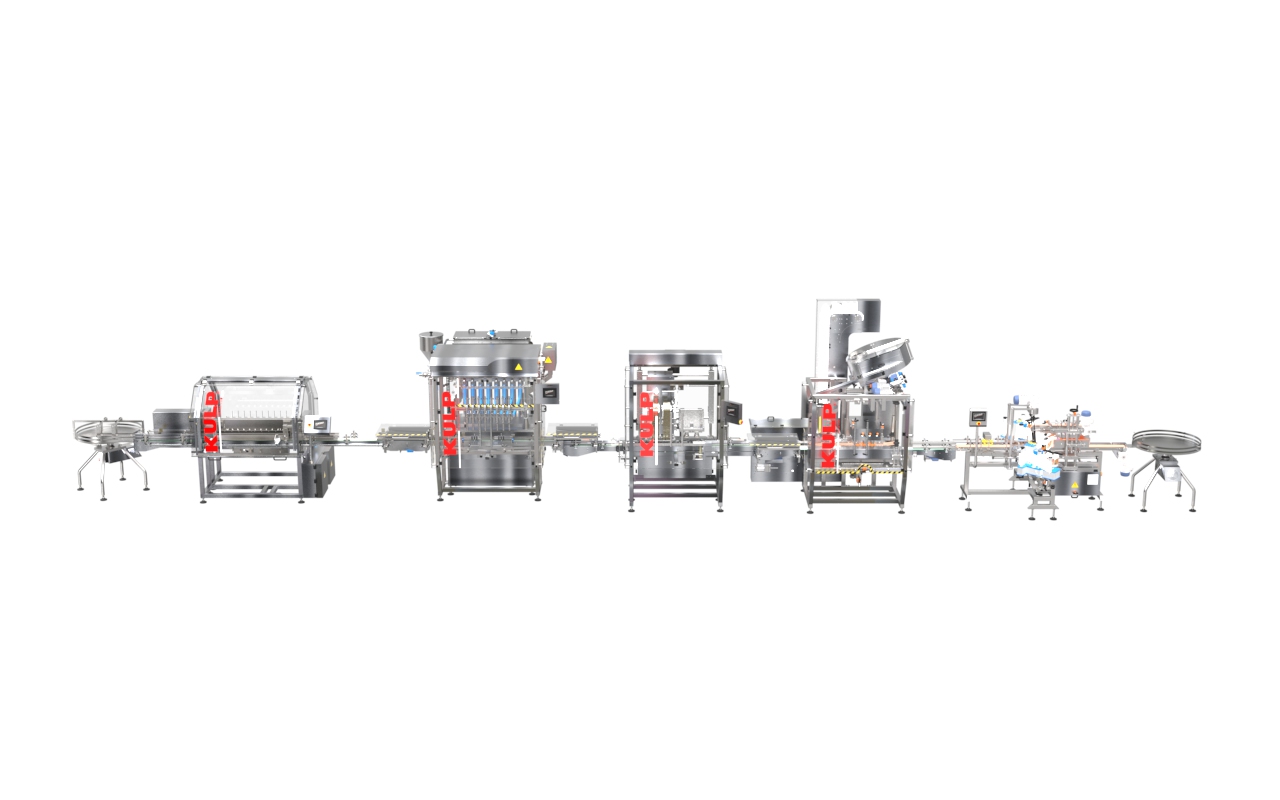

. JARS & BOTTLES LABELING . LABELING OF ELLIPSE, OVAL, RECTANGLE AND SQUARE PACKAGES . CAPACITY: Up to 4800 Packages/Hour . ± 0.5MM LABELING ACCURACY - Touch Screen control panel - User friendly interface software in several languages - Flexibility for a wide range of containers for now and in the future. - Heavy duty stainless steel frame. - Easy adjustments by hand wheels and numerators. - Can dispense labels for max 100 in width (optional label dispensers for max 200mm). - Stepper motor controlled label dispensers. - Specific photocells for transparent labels. - Optional angel adjustment device for conical packages. - Optional hot-foil printers.

IDEAL FOR JARS AND BOTTLES UP TO 4800 PACKAGES/HOUR . INCLUDES : - FEEDING TABLE - AIR or WATER RINSER - FILLING MACHINE - CAPPING MACHINE - LABELER - COLLECTING TABLE The filling line may or not contain the following items up on the customer s request: - FEEDING TABLE: To dispatch the containers in a sequence into the convoyer system of the filling machine - RINSER: To blow away all dust and glass residues from the glass jars - FILLING MACHINE: To fill the product with high capacity and extreme precision - CAPPING MACHINE: To sort the caps, place them on the containers and close them. - LABELER: To label the packages with self adhesive labels - COLLECTING TABLE: To collect the packages from the labeler at the end of the packaging line Every single machine on the line works in synchronization with the previous previous machine for an optimal working capacity.

No represented companies found.

- KULP AMBALAJ MAKİNELERİ

TR

TR