| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MARİPAK AMBALAJ ENDÜSTRİ MAMÜLLERİ SAN. TİC. A.Ş.

Şerifali Mah. Serdivan Sok. No: 60 / Ümraniye / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 365 8570

|

Hall: 12

Stand: 1207A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

In the shrink wrapping and flexible film packaging industry, we have always been pioneers in producing top-notch packaging machines without compromising on quality. Dedicated to perfection, we take pride in seeing our packaging machines functioning all around the world. With a growing network of distributors, we operate in over 40 countries. No matter where you are, we have a shrink-packaging solution for your product!

Advantages: 800 1200 parcels/hour ready to ship packaging capacity Packages that have similar width and height but different lengths can be wrapped automatically E-commerce & automatic mailing automation system with ready to ship labeling Ability to integrate to the company server systems to upload shipment information Optional Functions: Print & Apply labeler eg. carrier ready shipment label, digital invoice etc. Barcode reader compares product info with wms Check-weigher unit If weight of product is registered Discard pusher for checkpoints discards parcel for inspection Film folding unit to fold flat film Registered film sensor for printed film application for company themed films Remote access control Custom power supply options for different electricity requirements Flexibility: Native languages can be uploaded Warning messages for potential emergency cases Navigation Control for actual throughput and estimated packs/time unit

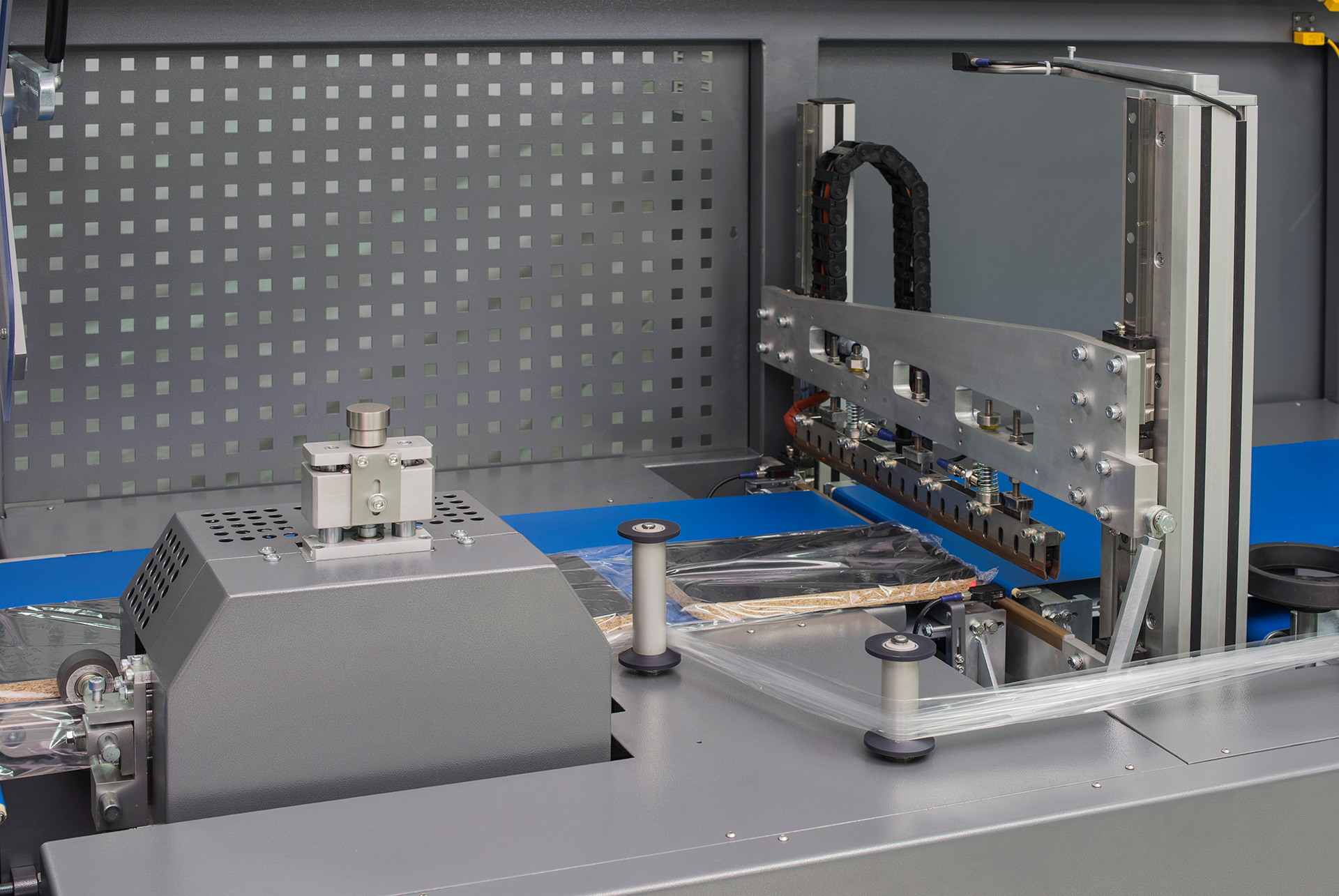

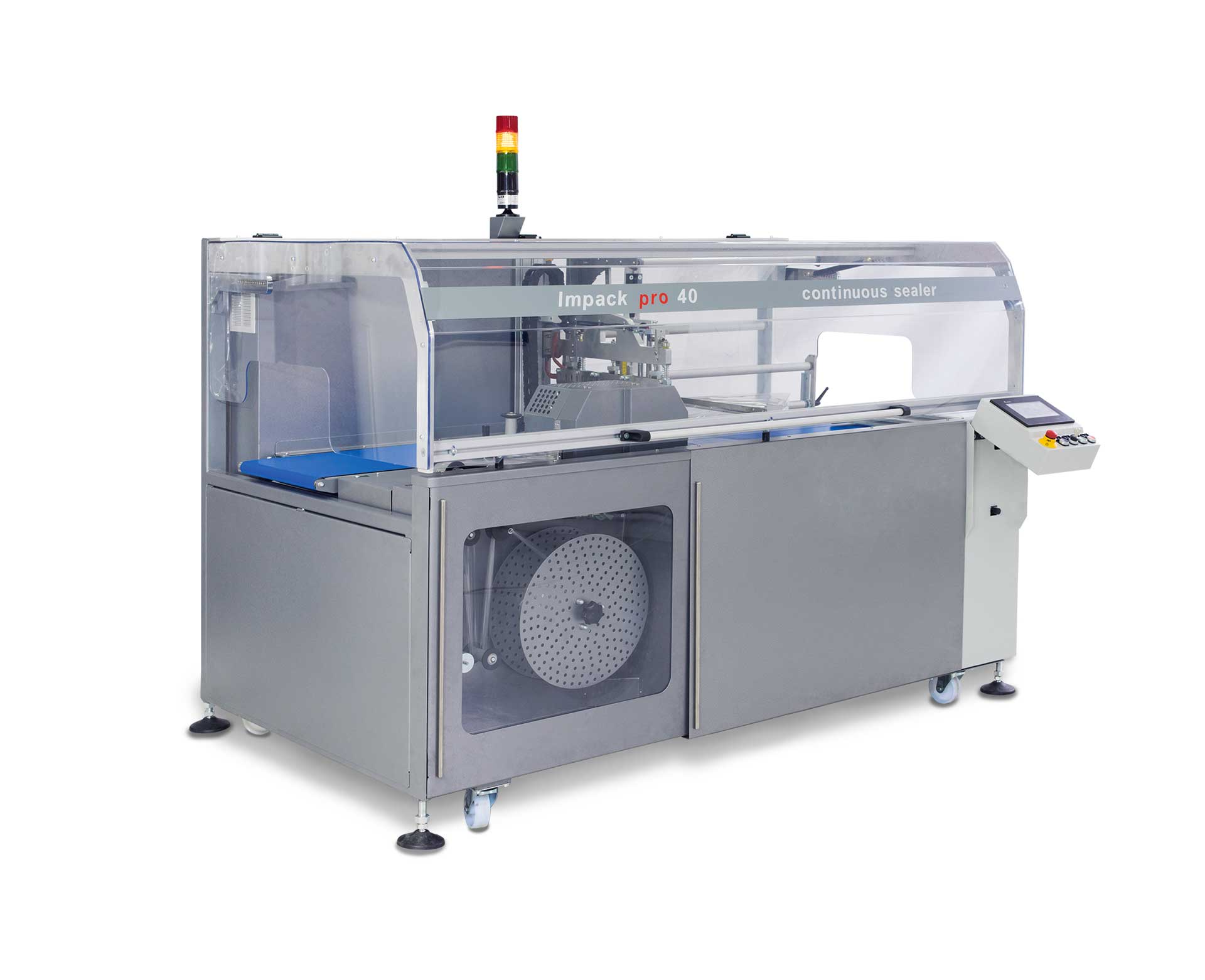

Advantages: Nonstop operation with continuous motion system Dual axis servo motor driven cross sealing High precision and consistency with cross and side seal Packaging with no length limit Control of film quantity on the 4 sides of packages for saving results Minimized layout requirement by compact single-chassis design Reduced energy & increased safety Features: Touch control panel with color screen Encoder controlled speed & length aware synchronization Easy format change for different package sizes Regular or finger pitch conveyors for feeding can be applied Ergonomic operator panel with most useful hard buttons Up-to-date safety electic and mechanic measures of CE directives Cross and continuous knives with PID controlled heaters Automatic film dispenser with tension control Photocell controlled package distance positioned feeding Automatic length detection option Sealing: Film sealing under no distortion with non stop and tight operation Up to 15% advantage in film consumption Film tension releasing on the cross-sealing point Trim winder is designed to control very thin films without breakage Height adjustable cross sealer (Optional motorized) Adjustable Central Sealing for varied package height applications Flexibility: Native languages can be applied Recipe application with different package dimensions Warning messages for potential emergency cases Navigation Control for actual throughput and estimated packs/time units Optional: Double seal feature on cross sealer for high thickness or PE material Control of external infeed conveyor through operator panel Vertical photocell to detect thin packages Printed marker registered film detection & application

Advantages: Very compact and more esthetic new Pro design version Continuous side sealer provides unlimited length packaging ability Very fast and flawless sealing property by Servo driven vertical sealer Easy to integrate with the production lines directly Recordable and re-callable temperature and position adjustments Features: Automatic length detection by sensor synchronized with encoder control User-friendly colorful touch screen operator panel Automatic packaging film drive with tension control Automatic trim winder with tension control Feeding frequency control by sensor detection and PLC command Sealing: Center-Seal property provides accurate and linear sealing line Adjustable precision and pressure on cutting and sealing force PID controlled sealing temperature inserted by touch panel Alternative sealing blade structures for various packaging material Product clearance control under seal bar by sensor Flexibility: Easily adjustable for varying product sizes and capacity requirements Various language options and adaptable touch keyboard Memory Receipt property for prompt adjustments Experienced design of sealing blade compatible with broad range of thickness Optional: Solenoid actuator for side sealer: Free of compressed air requirement Printed film applicability by marker detection sensor and programming Ability to use single layer flat film by center-folding unit Ability to control additional conveyors by inverter

Advantages: Feasible fully automatic solution for average capacity requirements Easy to integrate with the production lines directly Easy-to-reach spacious design for both maintenance and adjustments Features: Automatic length detection by sensor synchronized with encoder control User-friendly colorful touch screen operator panel Automatic packaging film drive with tension control Automatic trim winder with tension control Linear sealing ability for various heights by Center-Seal system Feeding frequency control by sensor detection and PLC command Ability to read instant (or total) realized capacity by counter L bar opening limit control by electric servo system L bar sealing pressure control system Trimmer system with safety sliding window with safety sensors Roll nesting unit with CE competible safety doors Fixed legs and casters together for both option Visual and audio warning signal for film tension variance detection Strong needle-wheel frame structure for air discharge perforation Sealing: Fully Teflon coated L shaped hot bar-knife system PID controlled sealing temperature inserted by touch panel Alternative sealing blade structures for various packaging material Product clearance control under seal bar by sensor Flexibility: Easily adjustable for varying product sizes and capacity requirements Various language options and adaptable touch keyboard Recordable and re-callable product value adjustments User friendly designed trim-winder for easy and prompt trim unloading Separated film roll cabinet for easy and prompt loading On-screen adjustable frontal and hinder gaps Optional: Proper passage of short products by Linking Conveyor Printed Film applicability by marker detection sensor and programming Ability to use single layer flat film by Center-Folding Unit Ability to control additional conveyors by inverters Pneumatic sealing with less option to target economic solution

Features: Reduced energy consumption by double layered isolation room Bottom embedded heat chamber and fan system Perfectly dissipated heat inside via adjustable flaps and channels Conveying speed control to optimize heat treatment duration Instant switching from PE to POF by chain lift-up system (T45 & T60 only) Automatic cool down to 70ºC before switch off Easy to integrate with all types of packaging machines directly Equipped with caster wheels & brakes, easy to re-position in facility PID controlled accurate heat adjustment Circulation fan speed control to optimize air flow rate Long lasting covered tunnel conveyor spindles Color: Metallic Dark Gray (RAL Code: Customized Mixture) Optional: Alternative conveyor types: Wire Mesh, Teflon Mesh, Plastic Mesh Higher chamber and frame designs are available Ironing Rollers at discharge for side smoothing of PE wrapped package PE Cooling Fan at discharge for fast cool-down of PE wrapped package Exhaust gas hood can be applied if required by application Stainless steel versions are available for wet/moist working environment Recordable heat and speed via touch panel controller Safety Measures: At the infeed and discharge points of the tunnels metal protection shields are applied to avoid human contact to high temperature surfaces. Conveyors stop automatically during jams to avoid further problems. Against high temperature or fire risk, in case of the stop of the conveyor or fan circulation, the heaters are isolated automatically. Tunnel fan have been protected with mesh guards and operator hands can not be contacted.

No represented companies found.

- MARİPAK

TR

TR