| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MARMARA MAKİNA KALIP MÜH. MÜM. SAN. TİC. A.Ş.

Semizkumlar Mevkii Başkumandan M. K. Atatürk Cad. No: 50 / Silivri / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 711 3728

|

Hall: 11A

Stand: 1171A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

MARMARA MAKİNA KALIP was established in 1974 in Istanbul Silivri which has been operating in the Metal Packaging Industry since 1987. The main topics we serve are as follows; Machines for tin can manufacturing, plastic bottle and sheet molds, tools and spare parts, Tin can Seaming and Lug Caps Closing Machines, tools and spare parts for Food Industry, Machinery repairs, maintenance and revisions, Custom made Conveyor Systems, Engineering services on a Project basis, Custom made Productions on a part basis. Marmara Makina Kalıp is a leading supplier in its field which aims to be a competitive and reliable manufacturer in its market by accelerating R&D activities with its innovative works. In recent years, Tin Can Seaming Machines, Lug Caps Closing Machines and Spot Welding Machines have been main parts of the production. Designs can be made with CAD/CAM or CAE programmes, high precision parts can be processed with latest technology CNC machines and dimensionally controlled with CMM in the factory today. Besides, The plant is maintaining to support the food industry with its 50 years of experience. The company exports machinery, molds, tools and spare parts to many countries as Asian, Middle Eastern, North African, the Balkanian, U.S.A and France.

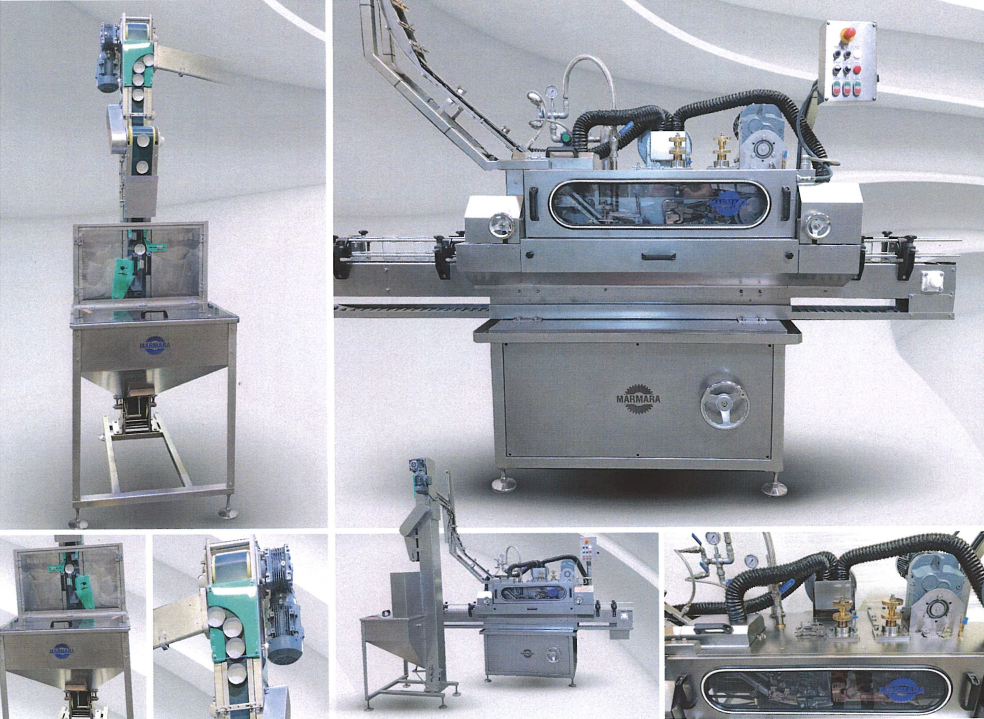

This fully automatic seaming machine is designed and built for seaming the bottom or top of round tin cans. It has 4 seaming stations working on the rotary system and works on the principle of rotating can. The lower tables are driven by the motor, rotate in synchronism with the upper chucks. The machine has fully automatic can and lid feed sistems. It has an extra motor that makes it easier to adjust the height according to can . The machine has large size range for seaming of the different cans. Also it has own automatic lubrication system.

Full Automatic Lug Caps Feeding, High Capacity, Easy Adjustment And Usage, Working Without Compressed Air.

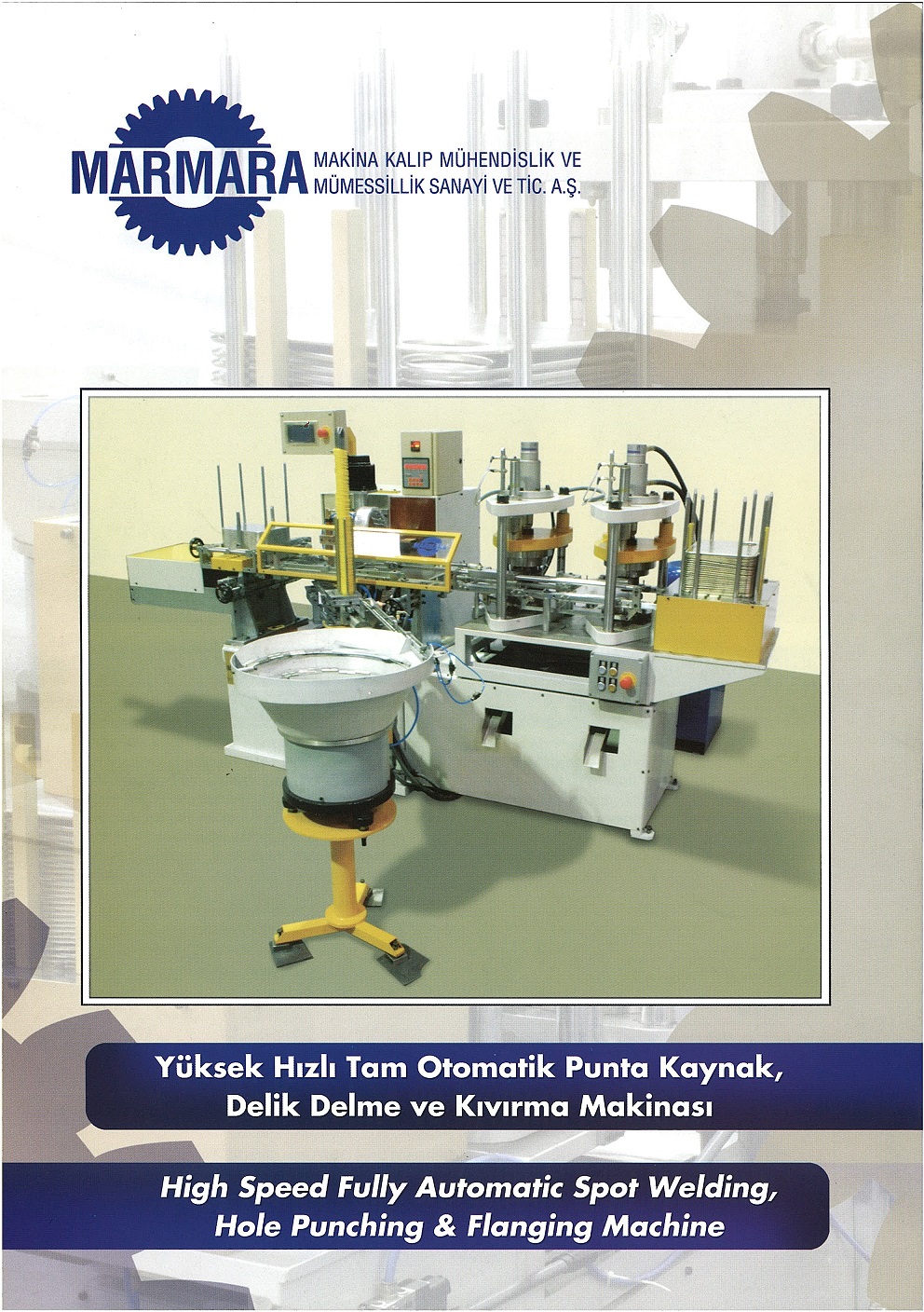

This machine is designed to combine the spot welding, hole punching and flanging operations on a rectangular tin can end. The machine enables the user to minimize the production personnel, the work in process, the energy consumption and it maximizes the output and profit in the manufacture of the rectangular tin can ends. The machine can be designed for different end types and dimensions End feeding and spot welding system are driven by servo motors.

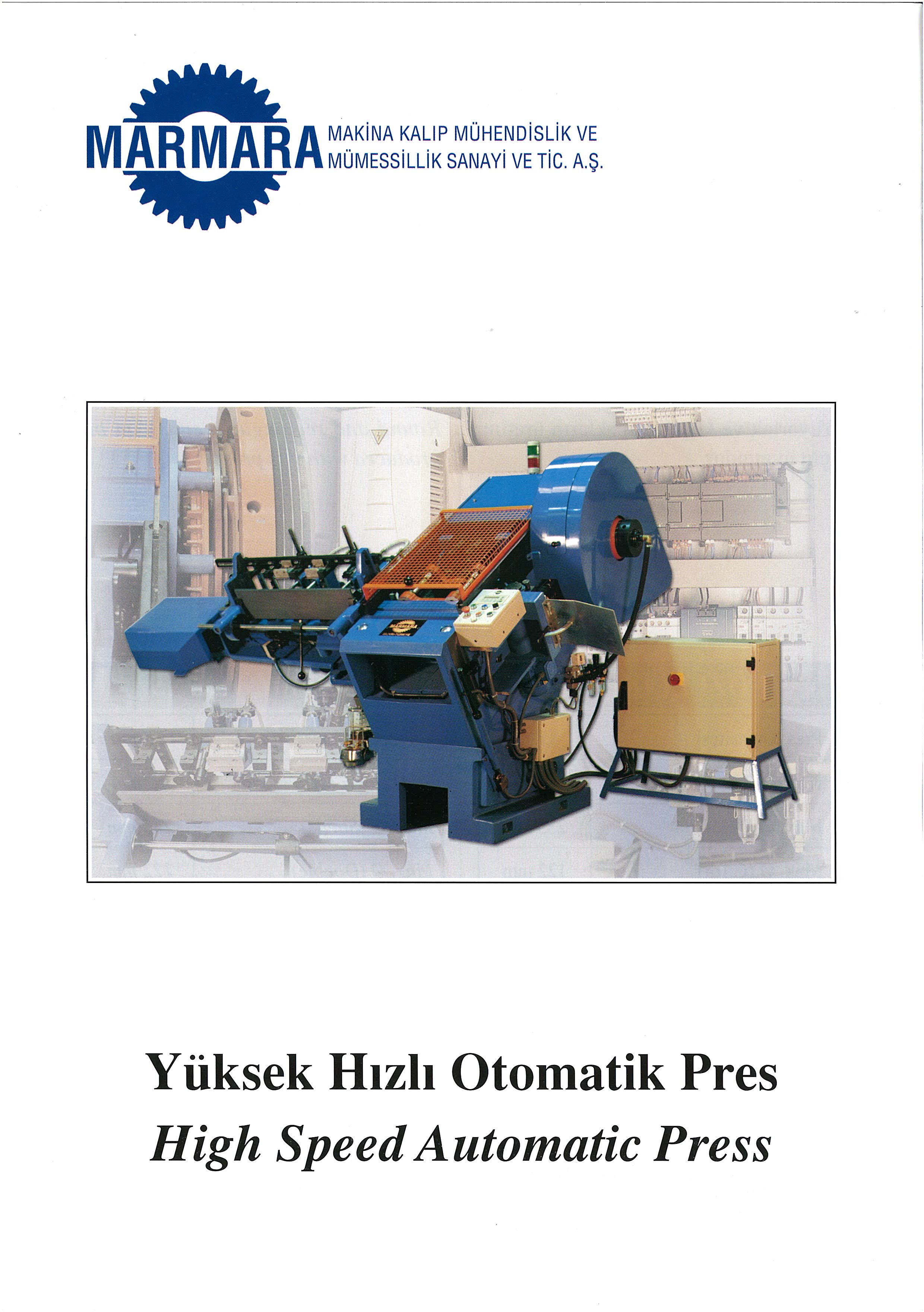

This Speed Automatic Press This press is designed to produce ends of any size. Slit or scrolled sheets can be used. This press can be arranged for double- die and single die. Round and rectangular ends can be produced with this press.

The Marmara leak testing machine is applied to tin can manufacturing lines. The electronic test system installed in this machine guarantees the highest precision and relia- bility for leak free tin cans. The Marmara leak tester height adjustment can be made very simply. All control systems are clearly arranged which allows easy adjustment of the machine.

No represented companies found.

The company has no registered brand information.

TR

TR