| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MERTSAN TEKSTİL VE AMBALAJ SAN. TİC. LTD. ŞTİ.

Güneşli Mah. Üsküp Cad. 1363. Sok. No: 23/B / Bağcılar / İSTANBUL / TÜRKİYE

|

Contact Info: +90 542 432 1703

|

Hall: 12

Stand: 1225A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Our company was founded in 1992 by Erdem Nezih in the field of manufacturing of machinery honest, reliable and serves the evolving structure. With his new breakthrough in the manufacture of machinery, is expanding its product range with each passing day. MERTSAN MACHINE Food Stretch, pallet stretch and aluminum foil rewinding machines Plastic and Packaging machines Bobbin transfer machines Lamination machines In matters that can respond to customer needs in the best way, in terms of special features that can be incorporated mechanical and electronics has been manufacturing high quality machines. Gained importance in our country where automation is the way of industrialization, the demands of our customers about special features taking into consideration the machines we manufacture and maintenance services in the after-sales service by carrying out customer satisfaction are always kept in the foreground. In-country and abroad, the Czech Republic, Bulgaria, Romania and many Arab countries, with sales increasing demands of our machines in order to realize with time and increasing quality we are directing our investments in most intelligent manner. OUR OBJECTIVES To accelerate Machinery manufacturing promotion of domestic and foreign fairs to attend. Redirect professional consciousness and understanding of our work, our employees are trained and skilled to provide the highest quality service. Our goal in the manufacture of machinery to expand our product range,increasing our diversity. Friendly, disciplined, honest work, with our understanding of the good business relationship with our customers and build friendships are rooted.

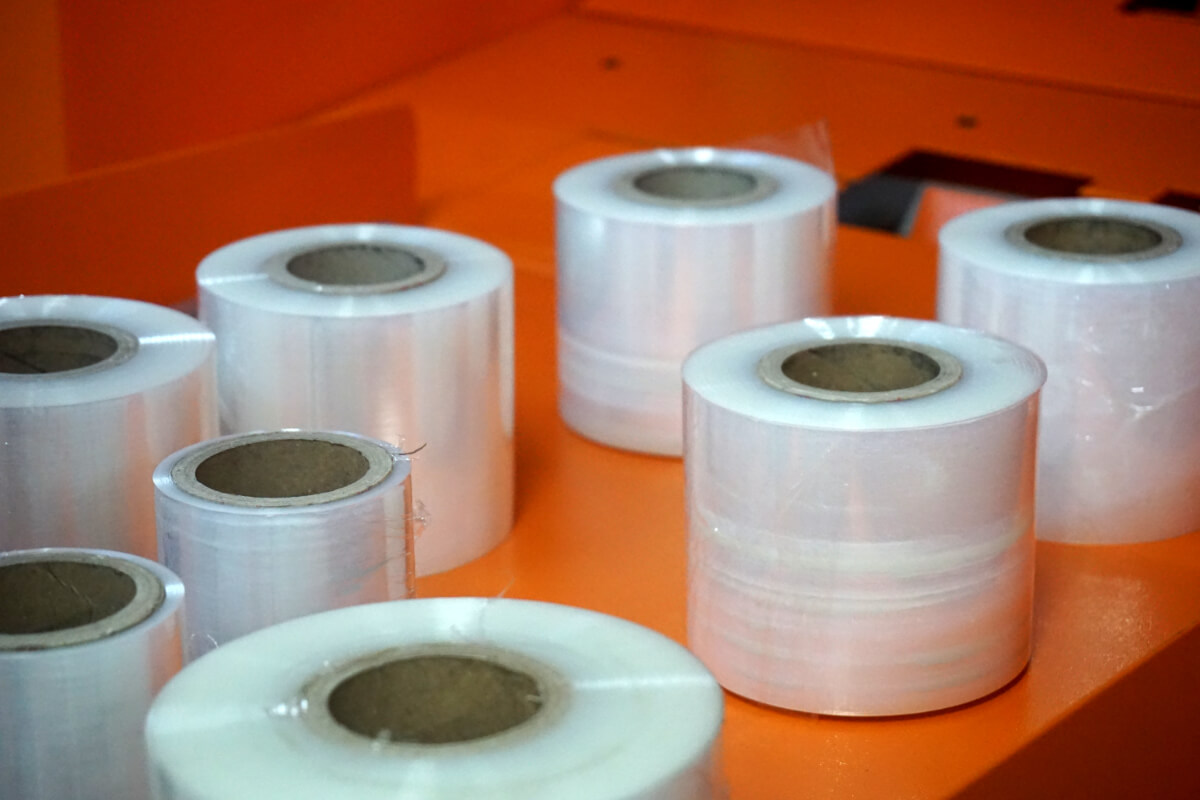

Fully Automatic stretch rewinding machine Cling Film and Industrial Stretch can be rewinding. With special sensors, it stops working and warns the user in case the stretch runs out, the stretch breaks or the stretch breaks. Automatic product weighing and automatic calibration system. ( Optional ) High rewinding speed (1100 m/min) Automatic bobbin feeding system. Bobbin control sensors. Manual stretch edge adjustment system ( Optional ) Adjustable bobbin storage for different bobbin sizes. Electrostatic paint and galvanized metal parts. Rewinding quality that does not deteriorate at high speeds. Pneumatic system supported operation. Pneumatic pressure adjustment. User-friendly design with PLC control. Color Touch LCD control panel. Electronic regulation system. (max. 270V min. 180V) Low voltage control system for safety reasons. ( 24v dc ) Intelligent calibration system with PLC control software

Fully Automatic stretch rewinding machine Cling Film and Industrial Stretch can be rewinding. Specially designed blade and roller system for stretch slicing. Five slicing blades with adjustable spacing. Specially designed wide rewinding range (min. 10 m max. 1500 m) With special sensors, it stops working and warns the user in case the stretch runs out, the stretch breaks or the stretch breaks. Automatic product weighing and automatic calibration system. ( Optional ) High rewinding speed (1100 m/min) Automatic bobbin feeding system. Bobbin control sensors. Manual stretch edge adjustment system ( Optional ) Adjustable bobbin storage for different bobbin sizes. Electrostatic paint and galvanized metal parts. Rewinding quality that does not deteriorate at high speeds. Pneumatic system supported operation. Pneumatic pressure adjustment. User-friendly design with PLC control. Color Touch LCD control panel. Electronic regulation system. (max. 270V min. 180V) Low voltage control system for safety reasons. ( 24v dc ) Intelligent calibration system with PLC control software

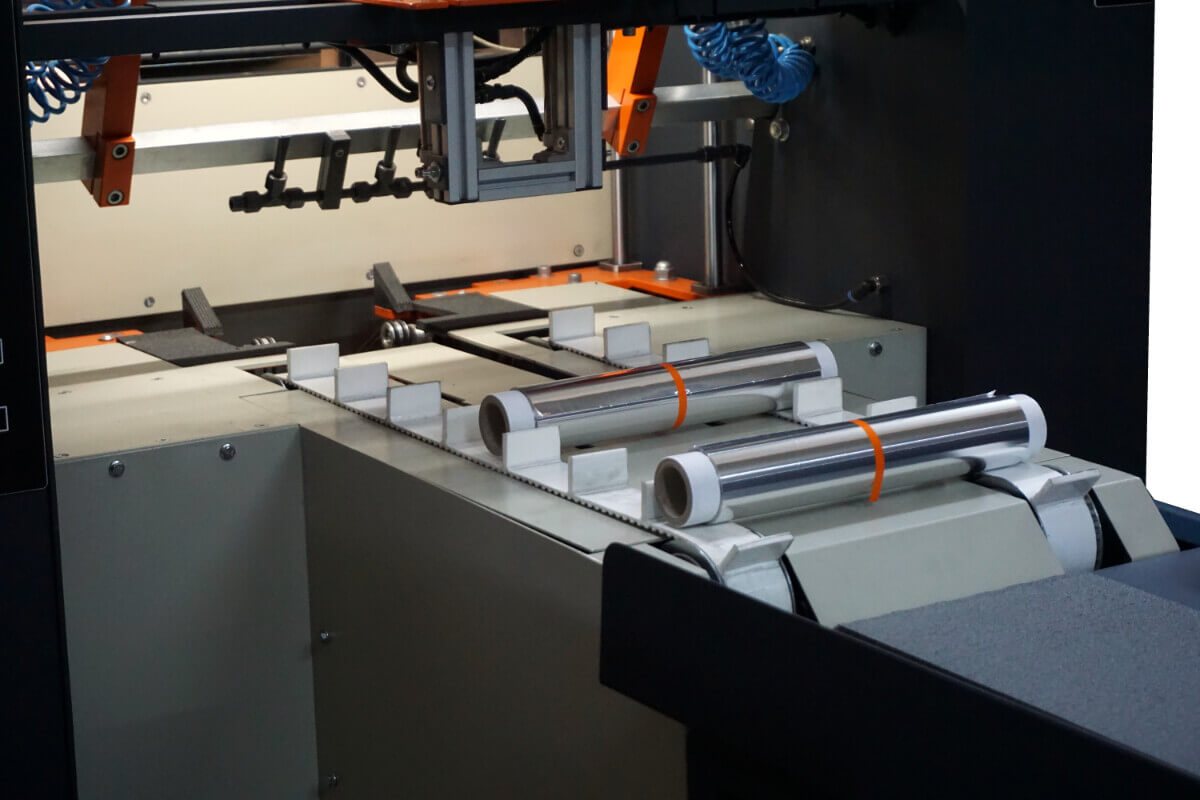

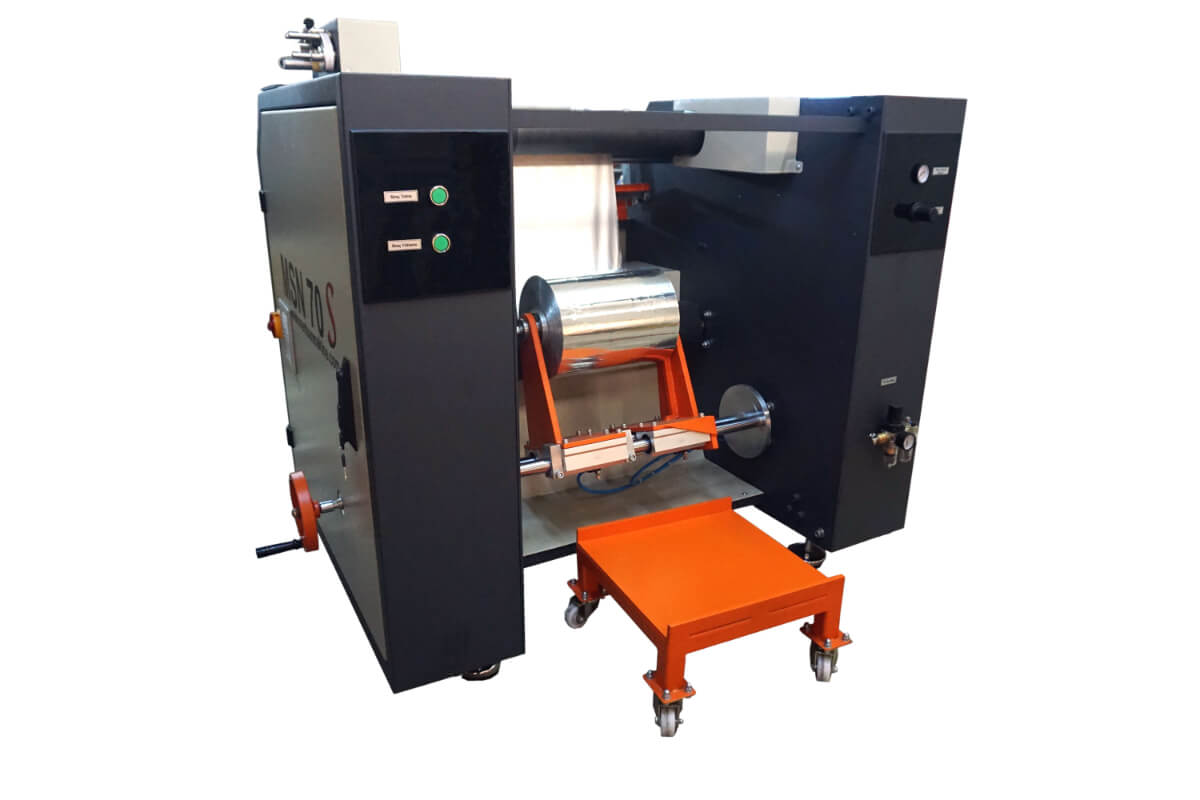

Fully Automatic Aluminum Foil and Stretch rewinding machine Specially designed wide winding range (min. 5 m max. 300 m) With special sensors, it stops working and warns the user in case the stretch runs out, the stretch breaks or the stretch breaks. Automatic product weighing and automatic calibration system. ( Optional ) High rewinding speed (1100 m/min) Automatic bobbin feeding system. Bobbin control sensors. Manual stretch edge adjustment system ( Optional ) Adjustable bobbin storage for different bobbin sizes. Electrostatic paint and galvanized metal parts. Rewinding quality that does not deteriorate at high speeds. Pneumatic system supported operation. Pneumatic pressure adjustment. User-friendly design with PLC control. Color Touch LCD control panel. Electronic regulation system. (max. 270V min. 180V) Low voltage control system for safety reasons. ( 24v dc ) Intelligent calibration system with PLC control software

Cling Film Industrial Stretch and Aluminum Foil can be rewinding. It facilitates bobbin change with its double rewinding head. Floor loading system for jumbo rolls. Automatic label dispencer system ( Optional ) Electrostatic paint and galvanized metal parts for health reasons. High rewinding speed. (650 m/min.) High measurement accuracy with encoder system. Automatic and Manual cutting options when the rewinding process is finished. Rewinding quality that does not deteriorate at high speeds. Pneumatic pressure adjustment. Intelligent control system with PLC control. Touch LCD control panel. Electronic Regulation System. ( max. 270V min 180V ) Working with low voltage for electrical safety reasons. ( 24V DC ) Easy and Comfortable user friendly design. Intelligent calibration system with PLC control software

Cling Film and Aluminum Foil can be rewinding. Pattern system on Aluminum Foil. Two pattern roller options for different patterns. It facilitates bobbin change with its double rewinding head. Floor loading system for jumbo rolls. Automatic label dispencer system ( Optional ) Electrostatic paint and galvanized metal parts for health reasons. High rewinding speed. (650 m/min.) High measurement accuracy with encoder system. Automatic and Manual cutting options when the rewinding process is finished. Rewinding quality that does not deteriorate at high speeds. Pneumatic pressure adjustment. Intelligent control system with PLC control. Touch LCD control panel. Electronic Regulation System. ( max. 270V min 180V ) Working with low voltage for electrical safety reasons. ( 24V DC ) Easy and Comfortable user friendly design. Intelligent calibration system with PLC control software

No represented companies found.

- MERTSAN MAKİNE

TR

TR