| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PİRMAK MAKİNA SAN. TİC. LTD. ŞTİ.

MARMARA SANAYİ SİTESİ R BLOK NO: 9 KÜÇÜKÇEKMECE / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 671 3619

|

Hall: 11A

Stand: 1173C

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Pirmak Makina was established in 1995 and produces pharmaceuticals, cosmetics, water, buckets, bottle shakers, paint, fruit juice, milk, honey, etc. It produces filling and labeling machines. Pirmak Makina was established in 1995 and produces pharmaceuticals, cosmetics, water, buckets, bottle shakers, paint, fruit juice, milk, honey, etc. It produces filling and labeling machines. By prioritizing quality, Pirmak provides a service above expectations with its staff in line with the aim of providing customer satisfaction in line with needs and demands. It provides services to many companies that produce products specifically and with emphasis on human health.

Our machine consists of six stations. It works with pneumatic control as a Rotary System. First, the glasses are manually fed into the magazines on the machine. At the first station, the glasses are dropped onto the star with the help of a piston. At the second station, the cups are filled to the desired weight. At the third station, aluminum foil is placed on the rim of the filled glasses. At the fourth station, the filled and foiled glasses are glued to the foil glass in a way that does not leak, with the sealing head heated by the resistance. At the fifth station, the date is stamped on the glasses that have been foil sealed. At the sixth station, all finished products are automatically removed onto the conveyor belt. The products are ready to be packaged.

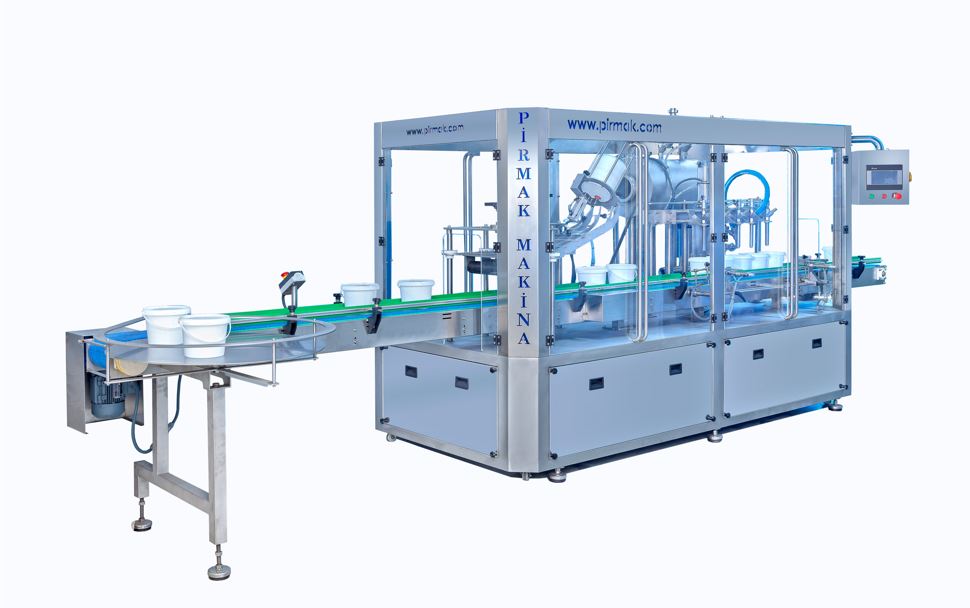

Our machines, designed for filling buckets, are completely made of stainless steel and are controlled by high-tech automation systems. It offers a hygienic filling environment with its plexiglass protection cabinet. Our bucket filling machine, designed according to the requested container and filling amount, is manufactured with two and four nozzles. After the automatic bowl taking, automatic filling and automatic lid taking processes, the bucket filling machine fills the products into buckets and delivers them to the output tray. With the bucket filling machine, results such as yoghurt filling, chocolate filling, hazelnut paste filling, cream cheese filling, honey filling and molasses filling can be completely achieved.

Pet Bottle Filling and Capping Machine works linearly in a pallet system with a mechanical transmission drive. In a system with a flow meter, plastic PET bottles of different sizes can be filled with milk and water with the help of a pump. The system starts filling from the bottom and gradually rises to prevent foaming during milk filling. Plastic pet bottles progressing on the line are capped in the capping unit and ready for packaging in the output tray. Pet bottle filling machine can fill milk, water, fruit juice, buttermilk filling and similar products.

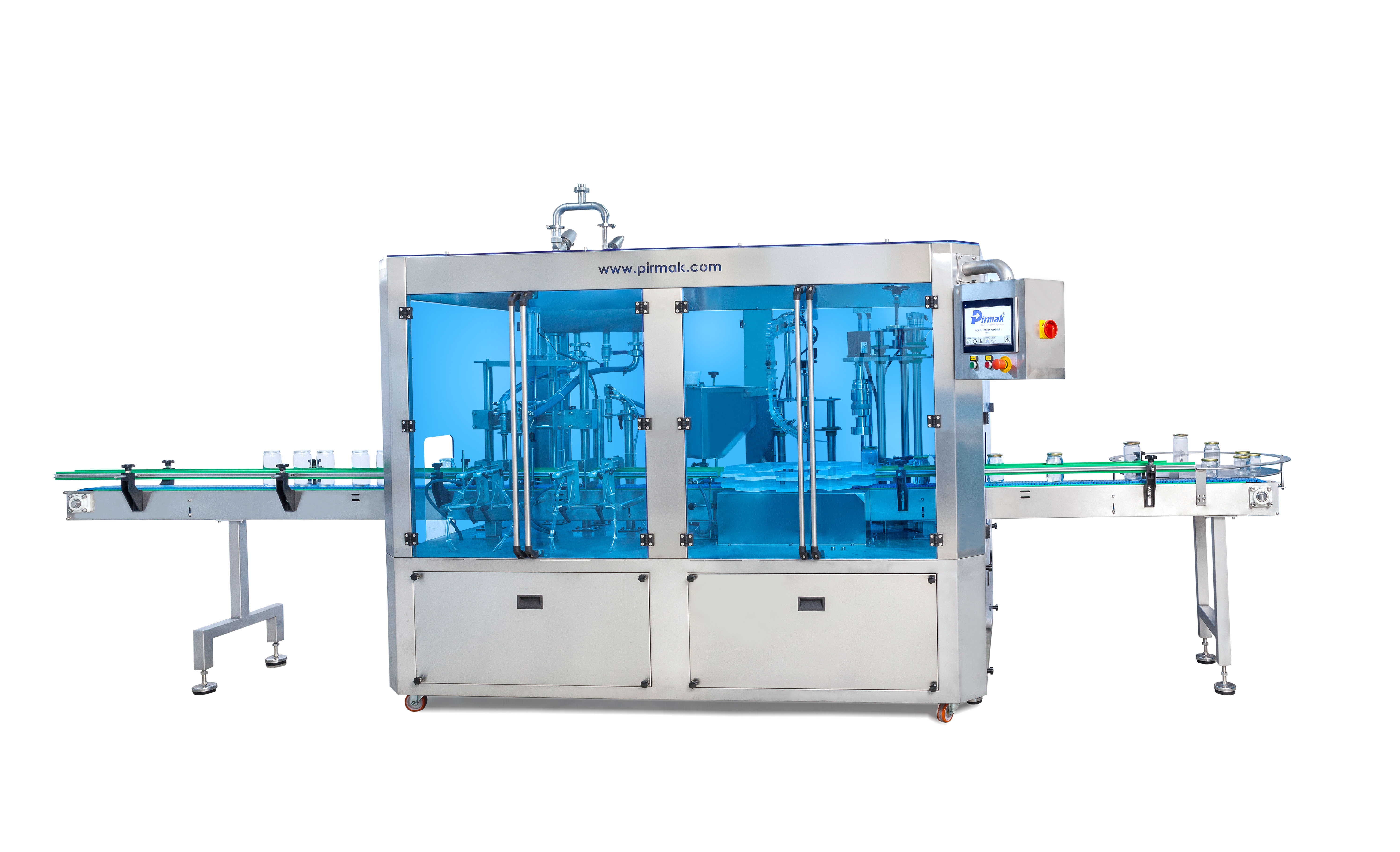

Jar filling and capping machine has a linear mechanical transmission in a pallet system. It works with propulsion. Glass jars of different sizes can be filled with the injector filling system. The system starts filling from the bottom, gradually rises and starts to foam during filling. It prevents. The glass jar advancing on the line is capped in the capping unit and placed on the output tray. is ready for packaging.

Empty bowls are manually fed onto the conveyor. 3 bowls moving on the conveyor are dropped onto the star with the help of a piston. It proceeds with the rotary system and is filled in the desired weight at the second station. The filled bowls are foiled to prevent leakage at the third station. At the fourth station, the bowls whose foiling process is completed are automatically closed and moved to the output tray.

No represented companies found.

The company has no registered brand information.

TR

TR