| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

STK MAKİNA GIDA MAK. İML. SAN. TİC. LTD. ŞTİ.

Sakarya 1. OSB 10. Cad. No: 5 Arifiye / / SAKARYA / TÜRKİYE

|

Contact Info: +90 264 281 5040

|

Hall: 11A

Stand: 1176A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

As STK MAKINA and MILKMAN MAKINE, we produce dairy machinery and equipment for dairy products such as pasteurized milk, yogurt, cheese, butter, cream, ice cream, and so on. We produce batch pasteurizers, plated pasteurizers, homogenizers, milk cooling tanks, milk storage tanks, cheese process tanks, and the other machinery and equipment which are used in the dairy sector to make dairy products. STK MAKINA is our mother company and MILKMAN is our international trade company, both of the companies belong to the same family and operate together. Furthermore, HOM-TECH is a brand that is used by both of the companies, we produce homogenizers under the name of this brand, and both of the companies have a right to share the rights of this brand. Although we produce dairy machinery and equipment, we define ourselves as a project company because we establish turnkey dairy plants. We have been working in this sector since 1981 and we have established hundreds of dairy plants in 107 countries all over the world. We would love to work with you on your projects as well.

Homogenizers are designed to lyse the particles in food products (oil and protein particles) to acquire a homogenized end-product. These units are most commonly used in milk, cream and yoghurt facilites. Homogenization application enhances consumption features, quality and shelf life of the products while also increasing the production output.

Pesteurizers are automatic systems which systematically heat up and cool down the milk by means of plated heat exchangers for the purpose of increasing the temperature of the milk without degrading physical and bio-chemical features (vitamins and diastases) of patogen bacretias and nutrients.

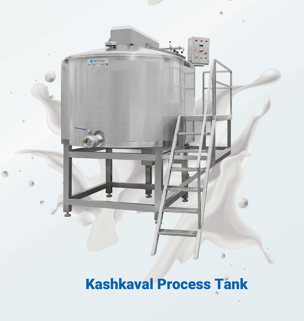

The milk is heated up to leavering temperature in Kashkaval Process Tank. When milk is transformed into curd before being cut by special mixers inside the tank.

Enclosed Type Dry Cooking Machine; enables remolding of the curd, placed in a circular boiler by means of the steam that circulates around the boiler. Open Steam Type Dry Cooking Machines are used for high capacities over 100 kg/charge. By means of 2 spirals provided, the curd is remoulded. Thanks to the steam; which is both provided inside the machine and around outer walls; the cheese is cooked as desired.

In this unit, all analogue cheeses, cream cheeses, chocolate sauces, tomato sauces, mayonnaise, ketchup, special cake sauces, ice creams, ice cream musks, hummus etc. products are prepared.

No represented companies found.

The company has no registered brand information.

TR

TR