| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

XIAN AEROSPACE HUAYANG MECHANICAL & ELECTRICAL EQUIPMENT CO., LTD.

No.1399, Changzheng 2 Road, Chang an District, Xi an, Shaanxi / / / CHINA

|

Contact Info: +86 29 8560 9188

|

Hall: 12A

Stand: 1290B1

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Xi An Aerospace-Huayang Mechanical & Electrical Equipment Co., Ltd (hereafter called as Huayang) is a leading company specialized in developing and manufacturing printing & packaging machinery, including CI flexo press, gravure press, wallpaper production equipments, carton preprinting press, and coating machine etc. Huayang has won more than 60 national patents and also introduced advanced technology from Europe. Through years efforts, Huayang has achieved state-of-the-art technologies and high manufacturing quality recognized worldwide. With a mission of Commitment to Excellence , our R & D team, with more than 120 experts in the field, is constantly dedicated to improving the quality, performance and range of applications according to needs of customers. Huayang s machines are characterized by the fast production, quick job change, high printing quality and user-friendly operation system. New innovations such as tension control technology, high efficiency drying technology, solvent residual control technology, guarantee precise, efficient and environment-friendly printing. All these advantages help our customers to be more competitive in the market and maximize their opportunities for success. This customer-oriented concept and win-win strategy has become a driving force for Huayang. At present, Huayang can supply full range of products including sophisticated machines and more basic machines to suit the economical preferences of the customers varying across the world with respect to each country s different culture and customer s requirement and target market. We would like to thank our existing customers home and abroad for their valuable and constant supports. We would present our commitment for more excellence in our products and services.

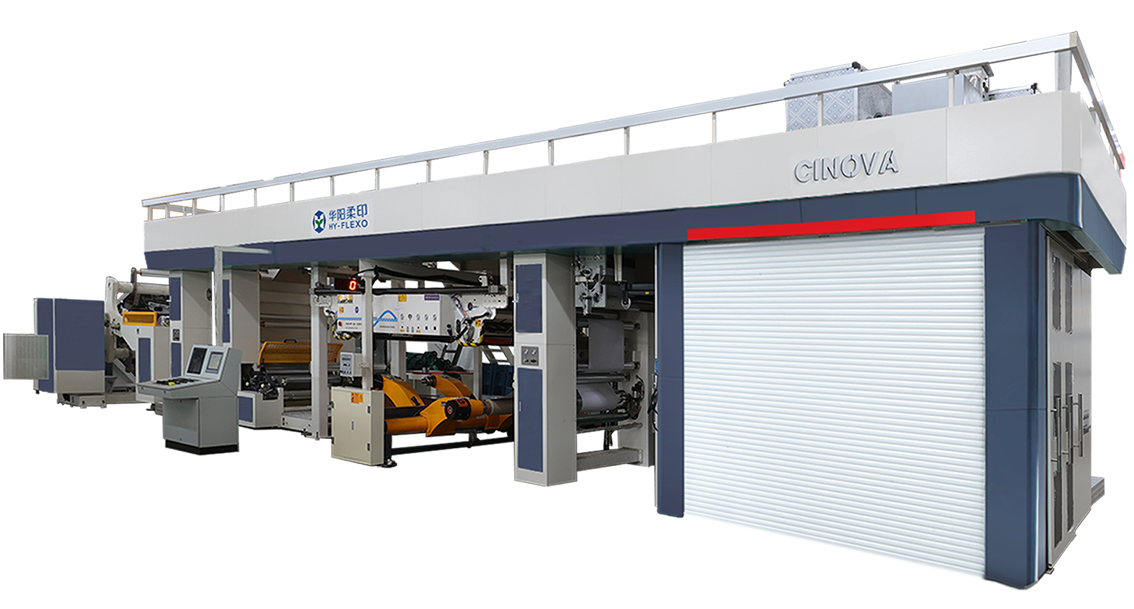

The Cinova.S CI Flexo Press (Film) is designed for the increasing demands for flexible packages. Reaching a printing speed of 600m/min, the Cinova.S is featured for its high automation, high productivity, user-friendly operation, and smart production management. Control and servo drive system Cantilever structure for anilox sleeve and print sleeve Central drum with constant temperature control system Close chamber doctor blade, reliable and easy for change Non-stop roll change (unload / load platform) Job management system Easy operation pre-register system Pressure servo control and pre-adjustment system Adjustable drying system Ink control and auto wash system Volatile gas recovery device System fault monitoring system Remote diagnosis and maintenance system

The Cinova CI Flexo Press (Film) is designed for the increasing demands for flexible packages. Reaching a printing speed of 400m/min, the Cinova is featured for its high automation, high productivity, user-friendly operation, and smart production management. Control and servo drive system Cantilever structure for anilox sleeve and print sleeve Central drum with constant temperature control system Close chamber doctor blade, reliable and easy for change Non-stop roll change (unload / load platform) Job management system Easy operation pre-register system Pressure servo control and pre-adjustment system Adjustable drying system Ink control and auto wash system Volatile gas recovery device System fault monitoring system Remote diagnosis and maintenance system

The Cinova-P CI Flexo Press (Paper) is designed for the increasing demands for paper packages. Reaching a printing speed of 400m/min, the Cinova is featured for its high automation, high productivity, user-friendly operation, and smart production management. Control and servo drive system Cantilever structure for anilox sleeve and print sleeve Central drum with constant temperature control system Close chamber doctor blade, reliable and easy for change Non-stop roll change (unload / load platform) Job management system Easy operation pre-register system Pressure servo control and pre-adjustment system Adjustable drying system Ink control and auto wash system Volatile gas recovery device System fault monitoring system Remote diagnosis and maintenance system

The E-Boss CI Flexo Press is designed for preprinting on different type of corrugated carton. Reaching a printing speed of 300m/min, the E-Boss is featured for its high automation, high productivity, user-friendly operation, and smart production management. SIEMENS control and servo drive system Cantilever structure for anilox sleeve and print sleeve Central drum with constant temperature control system Close chamber doctor blade, reliable and easy for change Non-stop roll change Job management system Easy operation pre-register system Pressure servo control and pre-adjustment system Adjustable drying system Ink control and auto wash system System fault monitoring system Remote diagnosis and maintenance system

The Supermachine 1200 Wallpaper Production Line combines rotogravure printing with screen printing to produce varities of wallpaper, which are based on PVC, non-wowen, and pure paper material. Germany technology, aerospace precision manufacturing. The first wallpaper machine combining servo control technology and automatic register in China; Preregistering before the machine running, which greatly improve printing quality. Printing images are static monitored in real time, which effectuates simple operation. Remote diagnosis system, which ensure real time troubleshooting. Large wrap angle deep embossing, quickly cooling and shaping technology; Pneumatic pressure system, without the limitation of the traditional embossing, which improves the embossing depth and precision. Energy-efficiency foaming oven, heat transforming efficiency is up to 92.5%. Embossing platform for quick change of rubber roll, first in China and easy for operation. Designed and manufactured according to CE standard. Optional printing register and embossing register.

The Release Film Coating Machine is mainly used for coating silicone release agent or a non-silicone release agent on the PET surface to provide a barrier adhesive. Application Fields: It can be used in many fields: adhesive products, medical/sanitary material, reflective material, waterproof materials, packaging and printing, and cross-cut processing.

The Cinova CI Flexo Press is designed for printing paper for aseptic liquid package. Reaching a printing speed of 400m/min, the Cinova-P CI Flexo Press is featured for its high automation, high productivity, user-friendly operation, and smart production management. Control and servo drive system Cantilever structure for anilox sleeve and print sleeve Central drum with constant temperature control system Close chamber doctor blade, reliable and easy for change Non-stop roll change (unload / load platform) Job management system Easy operation pre-register system Pressure servo control and pre-adjustment system Adjustable drying system Ink control and auto wash system Volatile gas recovery device System fault monitoring system Remote diagnosis and maintenance system

No represented companies found.

The company has no registered brand information.

TR

TR