| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ZAMBAK KAĞIT SAN. VE TİC. LTD. ŞTİ.

Yakuplu Mah. Hürriyet Bulvarı No: 1 Skyport Residence Kat 12 Daire 128 Beylikdüzü / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 536 356 3133

|

Hall: 2

Stand: 221

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Paper Converting and Paper Cup Production Machinery Experts! ZAMBAK KAGIT was established in 2003 to provide turnkey projects, which include infrastructures, machinery, equipment, raw materials, staff training, project management and consultancy services to the manufacturers of tissue paper products, toilet paper, nonwoven products, paper cups and disposable paper food containers. ZAMBAK KAGIT is the best supporter of the producers for all their production processes and always presents the best solutions for their requirements. Since 2003, ZAMBAK KAGIT co-operated with many international companies to be able to offer excellent optimal solutions to its clients. As a result of many successful international projects and extraordinary performance, ZAMBAK KAGIT has a leading place in paper converting machines, paper cup machinery, polystyrene machines industries in the East Europe and the Middle East. In addition, the company has the distribution rights of many international manufacturer companies, for the area that includes countries in the East Europe, Russia, Turkey, Cyprus, the Middle East and the Turkic Republic. In 2010, ZAMBAK KAGIT had made an investment to produce customized converting machines under its own brand. They are designed with Italian and South Korean technology and are under guaranty of the successful tradition of ZAMBAK KAGIT. With its fresh energy, ZAMBAK KAGIT will be the best partner for the producers in disposable products sectors. Our brand is known for delivering excellence, and therefore we have many references from big group companies to small workshops. Some of our references include In Turkey Lila Kagit, Yontem Kagit, Essel Kagit ve Seluloz, Viking Kagit ve Seluloz A.S, BIM Birlesik Magazalar A.S, Parteks A.S, Adnan A.S, AR Kagit, ... Beside them we have references in ARMENIA, AZERBAIJAN, BAHRAIN, BULGARIA, CHILE, ENGLAND, GERMANY, IRANIAN, IRAQ, IVORY COAST, KAZAKHISTAN, KOSOVO, LEBANON, LIBYA, MACEDONIA, MAURITANIA, MOLDOVA, MOROCCO, ROMANIA, RUSSIA, SAUDI ARABIA, SERBIA, SYRIA, TURKMENISTAN, UKRAINE, USA, UZBEKISTAN. All partner workshops that are producing our converting machines and equipment have ISO 90012008 and CE standards, teams with more than 600 employees to produce high-quality machines and equipment, and factory areas in between 20.000 m2 and 100.000 m2. ZAMBAK KAGIT s main aim is the business success of its clients. Therefore, we produce best quality, most efficient and hi-tech full line infrastructures with all required converting machines and equipment for producers. ZAMBAK KAGIT is offering complete solutions to the factories in its distribution hinterland with the support of leader companies in their industry and with its own deep know how.

ZKBM High Speed Paper Cup Forming Machine is adopted with the ultrasonic sealing station, so this model machine can produce various cups for hot and cold beverages, such as ice cream, yogurt, soups and snacks, by using single side or double sides PE coated paper. As one of our most popular models, it has its own compact structure. The machine runs steadily and fast and produces cups with good quality and lowest waste percentage. Therefore, it is the best choice for paper cup producers in terms of price/performance.

ZM-TK-450, adopts global advanced Programming Logic Control (PLC) technology and inverter controls machine speed. It is equipped with a servo winding unit and a touch screen operation panel. This machine has easy-operation, low-noise, high-quality features and it is the top choice for toilet roll or kitchen towel producers with its consecutive non-stop operation. 1. Non-stop type machine it continuously rewinds. 2. Each unit is driven by an independent motor (servo motor). 3. Simple structure decreases the failure rate. 4. Servo motor controls machine head and brake. 5. High-precision NC machine large diameter blade shaft, Siemens SIMOTION system and automatic blades axial slid function guarantee precise and clear perforation, and the rolls have finest tightness and diameter. 6. Perforation size could be set on the HMI. 7. Patented technology: uses the constant-vacuum system to start rewinding coreless roll, faster and with less wrinkles. 8. Optionally, the double-perforated blade can easily and quickly move from the perforation size of the small-diameter toilet paper, to the large-sized kitchen towel.

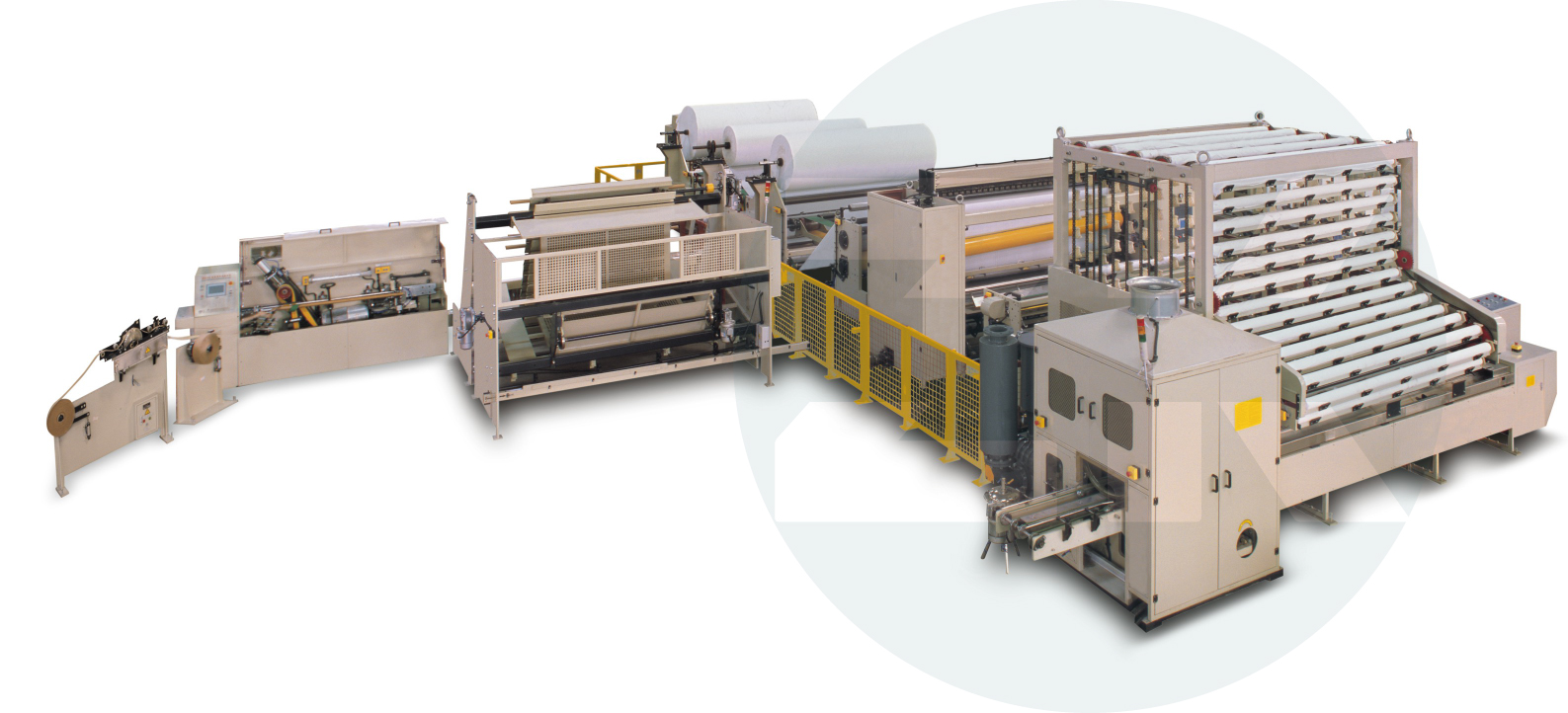

With our fully automated facial tissue production line, you can produce high-quality facial tissue products. This production line has the automatic functions of embossing, folding, counting, cutting, dividing, auto-taking, auto-dispatching, auto-transfer, and auto-sealing in one. In addition, it has the advantages of simple operation, high production efficiency, while ensuring the consistency of the finished products. With the fully automatic production, the amount of production labor can be cut down, so you can save from the production and managing costs. 1. Max. The width of the jumbo reel is 2950mm. 2. Horizontal style paper unwind stand: Raw paper line-placed is delivered paper with pneumatic wide belt and separate tension control device in each roll of raw paper. Optional pneumatic paper loading unit. 3. Web-edge controlling function: It will be installed on the paper unwind stand. The function is affected by a sensor to inspect and trace the web-edge, which is controlled by PLC. Then the sensor will transfer the data to the web-edge controlling performer to affect the aim of alignment of different paper webs. With this web-edge controlling function, the web edge of the different paper web will be kept in parallel with each other, even if the paper roll is transferring at high speed, which will reduce the wastage of paper roll edge. 4. The machine will alarm when the paper core or stainless steel tube is finished. 5. Auto-dispatching/taking device: This device can fulfill the instruction sent from the system accurately, count and divide the folded paper according to the requirements, and then send it to the dispatching device. 6. Dispatching device: It s to dispatch and transport the paper sheet to an auto-loading device. 7. Each unit is driven by an independent motor (servomotor). Simple structure decreases the failure rate. 8. Flexible controller arm is more convenience to operate. 9. Patented Technologies: simple and easy to maintain cutting blades & shafts structure and lower blade wastage have a character to protect blades and shafts. Folding roller manufacturing process significantly improves rigidity and vacuum adsorption, while the further effect is better folding accuracy and stability. The trimming top blade structure uses vacuum system to remove trimmed paper

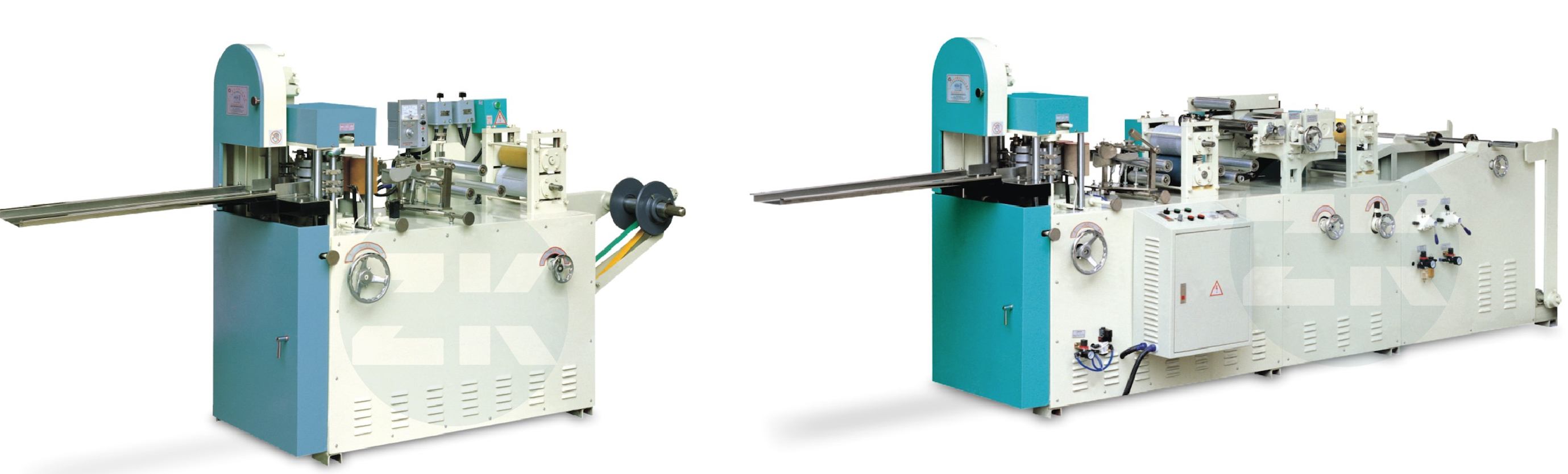

ZM-ZK model N Fold tissue -dispenser towel- machine with lamination, can fold the hand towel or wet towel into N shape after embossing and slitting with slitting roller. The products processed by the machine are mainly used in hotels, offices and kitchen for quick cleaning. Adopting with vacuum absorber, automatic counting and dividing device, it s superior in its speed and accuracy in counting. ZM-ZK-X model machine is equipped with a superior PLC technology; it has the HMI operating system. It is possible to change the configuration of the machine in line with the customers requests. These machines can be up to 11 lanes, if required. 1. Patented technology: cutting blades & shafts structure, the structure is simple, easy maintenance, lower blade wastage 2. Patented technology: bottom blades manufacturing process, stable vacuum adsorption leads to good folding accuracy and folding stability

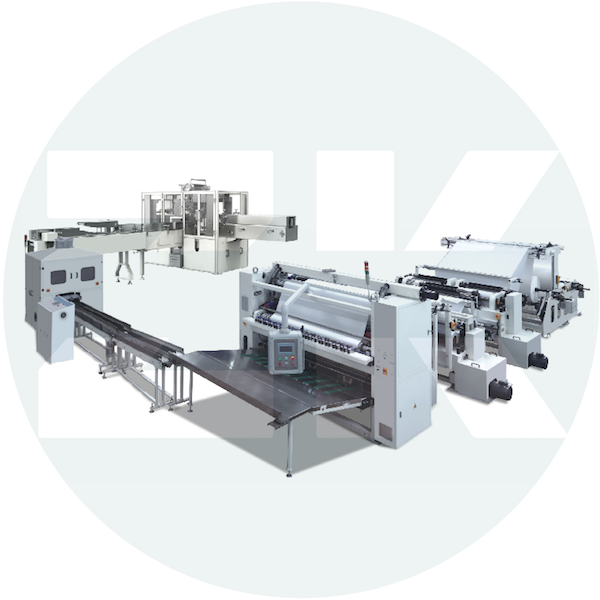

ZM-CML Handkerchief Production Line has an automatic counting and transfer units, which can be connected to the folding machine and automatic packaging machine. Since there is no need for any manual intervention, the productivity is increased with this production line. The production line controls the sheet stacking with the servo drive and guarantees the accuracy in counting. Control of the line is done via PLC with touch screen. The number of sheets counted can be determined via the touch screen. The line is equipped with detectors and warning systems against paper break and jamming.

No represented companies found.

- ZAMBAK KAĞIT

- ZAMBAK KAĞIT MAKİNE

TR

TR